Technology Overview as part of a Web-based

Technical and Regulatory Guidance

Permeable Reactive Barrier Systems

1. Introduction

Click

Here to view case study table at the end of this document.

![]()

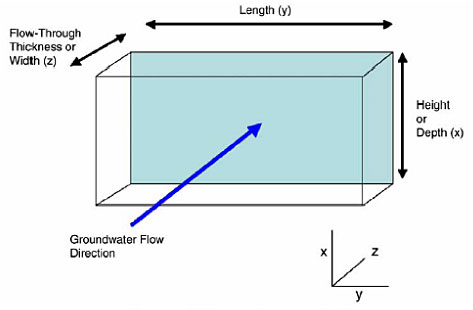

In the broadest sense, a permeable reactive barrier (PRB) is a continuous,

in situ permeable treatment zone designed to intercept and remediate a contaminant

plume. The treatment zone may be created directly using reactive materials

such as iron or indirectly using materials designed to stimulate secondary

processes, such as by adding carbon substrate and nutrients to enhance microbial

activity. In this way, contaminant treatment may occur through physical,

chemical, or biological processes. With most PRBs, the reactive material

is in direct contact with the surrounding aquifer material. The term “barrier”

is intended to convey the idea of a barrier to contaminants but not to groundwater

flow. PRBs are designed to be more permeable than the surrounding aquifer

materials so that contaminants are treated as groundwater readily flows through

without significantly altering groundwater hydrogeology (ITRC 2005).

2. Application

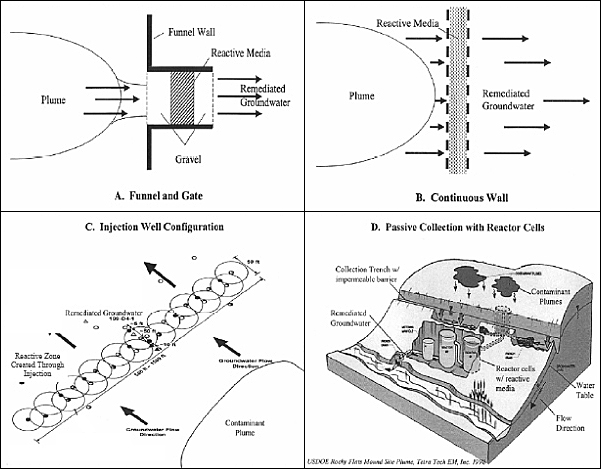

PRBs are often intended as a source management remedy or as an on-site containment

remedy. Therefore, PRBs may be designed with different site-specific objectives

in mind. For example, a PRB installed near the downgradient site boundary

may be designed to protect downgradient properties or receptors such as surface

waters or potable wells and reduce contaminants in groundwater to specific

numerical objectives. Alternatively, a PRB installed near the source may

be designed to reduce mass flux by a given percent, leaving monitored natural

attenuation or some other remedy to treat the residual downgradient contamination

(ITRC 2005). See Figures 1‑1 and 1-2.

3. Advantages

Advantages of using a permeable reactive

barrier include the following:

- passive operation

- relatively low costs of operation and monitoring

- most PRB designs do not include aboveground structures

4. Limitations

Using a permeable reactive barrier may

have the following limitations:

- The barrier system may not be a stand-alone technology.

- The remediation time frame may require a long treatment period, depending on the size of the contaminated area.

- Disposal issues could develop in the PRB treatment media after the contaminants are concentrated within the barrier system. This is most important in PRB systems that retain the contaminants (e.g., metals and radionuclides), as opposed to PRB systems which degrade the contaminants as they flow through the system (e.g., hydrocarbons and chlorinated organics).

- Biofouling and mineral precipitation may limit the permeability of the wall system if not managed properly.

5.

Performance

Hydraulic, geochemical, and microbial assessment of the PRB is all part

of the performance assessment of the PRB system. Evaluation of the longevity

of a PRB system has been examined using long-term column tests. Early systems

predicted decades before the PRBs will lose reactivity (ITRC

2005). Depending on several site-specific conditions, PRBs are now expected

to last 10–30 years before reactivity or hydraulic issues will result in

the need for maintenance.

6. Costs

The costs of PRB systems are comparable to those of other technologies. While

not as cost-effective as groundwater remedies like monitored natural attenuation

or bioremediation, PRBs compare favorably to groundwater pump-and-treat systems.

Since PRBs provide a mostly passive remediation technology, cost reductions

can be found in the operation and maintenance of the system. ITRC (2005)

provides site-specific examples of PRB system costs.

7.

Regulatory Considerations

Regulatory permits are not specifically required for the operation of a

PRB. However, one or more permits may be necessary for the design, construction,

monitoring, or closure of a PRB treatment system, to the extent that the

activity affects surface water, air, or groundwater quality or involves the

management of regulated waste.

Following is a list of key potential regulatory permits that may be required for a PRB:

- Underground Injection Control (UIC)

- National Pollution Discharge Elimination System (NPDES)

- Resource Conservation and Recovery Act (RCRA)

- Air Quality Control

- other discharge/construction permits

8. Stakeholders

Considerations

Stakeholders have previously expressed the following concerns regarding

proposed PRBs:

- In areas where there are preferential groundwater flow paths, it is imperative that it be demonstrated that total contaminant treatment can be adequately achieved with the PRB.

- A groundwater monitoring system should be put in place to monitor the PRB performance. The PRB is a passive technology and thus depends on the natural flow of the contaminant plume to pass through the PRB. It may take years for the complete breakdown or immobilization of all contaminants since the entire plume must pass through the PRB.

- When PRBs are used for precipitation of metals, it is not certain how long a PRB will be effective due to the reduced flow rate through the entire system.

- There is insufficient information about how existing or new environmental conditions may influence remobilization of contaminants.

- It is important that there is an evaluation regarding the potential leaching of reactive media or contaminants.

- When the PRB is used for precipitation of metals, the media may have to be removed and disposed of as a hazardous waste or contained in some other fashion.

- The remedial action work plan should address access restrictions (See Administrative and Engineering Control Technology Overview) during operation and maintenance. In addition, deed restrictions may be necessary if the PRB is left in place. Local authorities should be informed of potential disruptions to landscaping and other activities during replacement of the media.

9.

Lessons Learned

PRBs using zero-valent iron (ZVI) have been operating in the United States

since 1994. Considerable information has been collected on the performance

of PRBs since that time. Although not all the design and performance issues

are perfectly understood, this technology has grown significantly since the

early days. ZVI, the most common reactive media for PRBs, is used mainly

to treat chlorinated solvents although it has application to other contaminants.

See ITRC 2005, Section 2.4 for a more thorough description and list of metals

that can be treated with iron-based treatment media.

Table 10-1. Case studies including PRB treatment

| Nickel Rim Mine Site, Sudbury, Ontario, Canada (ITRC PRB-4, 2005) |

| Monticello Mill Tailings Site, Monticello, Utah (ITRC PRB-4, 2005) |

| Permeable Reactive Wall Treatment of Acid Mine Leachate at the Basin Luttrell Pit, Ten Mile Creek Site, Lewis and Clark County, Montana (R. Semenak and N. Kinghan, Kemron; G. Powell and S. Way, EPA) |

11. References

ITRC (Interstate Technology & Regulatory

Council). 1999. Regulatory

Guidance for Permeable Reactive Barriers Designed to Remediate Inorganics

and Radionuclide Contamination. PRB‑3. Washington, D.C.: Interstate

Technology & Regulatory Council, Permeable Reactive Barriers Team. www.itrcweb.org.

ITRC. 2005. Permeable Reactive Barriers: Lessons Learned/New Directions.

PRB-4. Washington, D.C.: Interstate Technology & Regulatory Council, Permeable

Reactive Barriers Team. www.itrcweb.org.