Technology Overview as part of a Web-based

Technical and Regulatory Guidance

In Situ Biological Treatment

1.0 Introduction

Click

Here to view case study table at the end of this document.

![]()

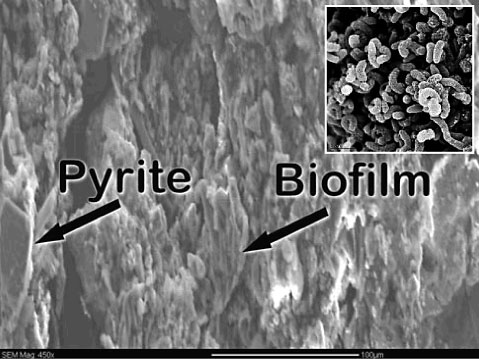

Figure 1-1. In an underground mine tunnel, green acid solutions flow across a bed of pyrite. Pink microbial biofilm communities can be seen along the margins of the stream.

(Photo by Jill Banfield, UC Berkeley)

In situ biological source treatment consists of isolating the source of mining-influenced water (MIW) through the establishment of an in situ biological layer on exposed metal sulfide surfaces (Jin et al. 2008b). This is typically accomplished through the injection of inoculum (e.g., wastewater effluent) and substrate (e.g., returned milk [Jin et al. 2008b]) into the subsurface material. The in situ biological source treatment can achieve satisfactory results without the cost of excavation and material handling. The process typically has two components: (a) developing an anaerobic environment through the injection and distribution of inoculums and substrates and (b) the formation of a biological film that impedes the release of products of iron reduction. The addition of materials that contain large populations of bacteria seeds the formation of biological films that thrive in the organic-rich anaerobic environment.

Isolation of the MIW source material from oxygen with barriers or diversions that are the result of microscopic organisms, chemical reactions, or both is the active mechanism of this application. A biological film or biofilm (see Glossary) that prevents access or encapsulates a particle by shielding the material from oxygen, prevents oxidation of the metal sulfides (Figure 1-1). Reducing exposure of the source materials to oxygenated environments prevents the subsequent release and distribution of the low-pH reaction products.

In situ biological source treatment is dependent on the ability to deliver adequate inoculum and substrate to the source material and maintain the biofilm on the particle surface. As in any in situ treatment, technology characterization, monitoring, containment, and treatment can be costly or sometimes operationally impractical due to the inherent complexities of working in the subsurface. Given adequate delivery and mixing of the substrate and inoculum, the performance of in situ biological source treatment should not be affected by particle size and surface area of the MIW source material. By managing the proper subsurface condition, a biofilm can be developed virtually anywhere in the subsurface.

The image in the Figure 1-2 was taken at 9450 magnification with a scanning electron microscope to illustrate the formation of an isolating biofilm attached to the surface of pyrite (Jin et al. 2008b). The enlargement in the upper right hand corner of figure shows a scanning electron microscope image of a piece of biofilm where communities comprise a very tight association of microbial cells. The biofilms can grow hundreds of feet underground in the absence of light and use iron and sulfur as energy sources (Jin et al. 2008b).

Figure 1-2. Biofilm growing on pyrite after 213 days in a microcosm filled with MIW.

(Source: Jin et al. 2008b. Photo enlargement Clara Chan, UC Berkeley.)

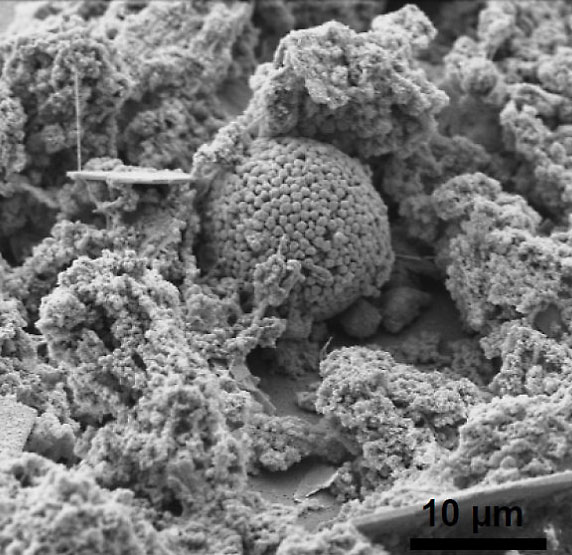

Research demonstrated that anaerobically growing microbial biofilm scraped from the inner surface of a borehole 1474 m below land surface within the South African Witwatersrand gold mine was found to possess framboidal pyrite (Maclean et al. 2005). Examination of the biofilm using a field emission gun scanning electron microscope equipped for energy dispersive X-ray microanalysis demonstrated that the framboids formed within a matrix of bacteria, exopolysaccharides, and nanophase ZnS precipitates (Figure 1-3).

Figure 1-3. Scanning electron micrograph of a typical framboid found with the bacterial biofilm.

The fine-grained material surrounding the framboid includes bacteria, exopolymers, and nanophase ZnS.

(Source: Jin et al. 2008b)

In situ biological source treatment may offer a much longer or even a permanent solution to the production of MIW. As with any biological solution, there are infinite variables that, if not managed, can affect the longevity and performance of the system.

Western Research Institute tested biological source treatment using inexpensive sources of inocula (e.g., wastewater effluent and solids, lagoon sediments) and substrates (e.g., returned milk and other dairy by-products) to raise pH and prevent MIW generation at the source (Jin et al. 2008b).

In another case, Waybrant (2002, in Daubert and Brennan 2007) developed simultaneous systems that increased alkalinity and removed metals by supporting the activity of sulfate-reducing bacteria (SRB). These investigations demonstrated that the slow-release and fermentable substrates most suitable for use in these systems are typically deficient in nitrogen, which is a limiting factor for SRB growth.2. Applicability

In situ biological source treatment technology is applicable to the following:

- MIW discharges with wide variations of both dissolved oxygen and concentrations of Fe3+ and Al3+

- a wide range of pH

- use as a stand-alone technology or in combination with other treatments

- source treatment and prevention of the release and distribution of low-pH reaction products

- applicable to any site that groundwater flow can be characterized or isolated

3. Advantages

Advantages of using in situ biological

source treatment are the following:

- low-cost materials and methods

- limited visual impacts and site disruption

- immediate and potentially long-term results

- wide climate applicability

- ease of construction and maintenance

- treatment of very large volumes of MIW-producing material is possible

- all the source material in a treatment area can be treated regardless of particle size/MIW potential

In situ biological source treatment of mine waste through the injection of oxygen-depleting materials, such as dairy or food processing waste, prevents the oxidation of iron. The introduction and growth of bacterial populations on the particle surface blankets the available surface contact area. Even though the “natural” condition of the groundwater can return, the biofilm can continue to shield or control contact of the oxidizing groundwater with the pyritic source material to control MIW formation. The bacteria have varying capabilities and longevity regarding the control of MIW formation and should be monitored routinely.

Jin et al. (2008a), Daubert and Brennan (2007), and Western Research Institute have done substantial bench- and field-scale testing of the in situ conditions that must be controlled to achieve positive results. These studies demonstrate that the overall practicality of the process to isolate the sulfate material appears to be dictated by site conditions and the ability to manage and maintain them.

An application of the technology (see Sequatchie Valley Coal Mine Case Study) is a source treatment of MIW. It also describes the use of electromagnetic surveys to characterize the subsurface conductivity down to 120 m and pinpoint sources of acid mine drainage. Additionally, electromagnetic surveys were used to monitor the change in groundwater characteristics attributable to the treatment. The results seem promising, but the area of influence is not delineated and additional treatment may be required.

In situ biological source treatment system can take place in most climates, although in extreme cold climates additional insulation may be required on surface support equipment. In situ biological source treatment should be pilot-tested to establish the proper treatment parameters for the specific site conditions and evaluate the ability to deliver and mix adequate inoculum and substrate with the MIW source material.

4. Limitations

Limitations of in situ biological

source treatment are as follows:

- variations in treatment materials

- clear delineation of the source

- clear delineation of the subsurface flow.

- undefined range of applicable geologic and geochemical conditions

- delivery and mixing of the inoculum and substrate or other treatment materials potentially difficult

- treatment materials potentially considered contaminants

After the biofilm is formed, the durability and sustainability of the isolating biofilm is questionable. Interactions between the various strains of anaerobic and aerobic bacteria may affect the longevity of treatment. In natural environments aerobic bacteria can eliminate anaerobic bacteria in the presence of oxygen. It is unknown if the more energetic aerobic organisms consume the anaerobic population, outperform them for access to energy sources, or the degree that oxygen may be toxic to anaerobic bacteria.

There is a wide variation in the inoculums and substrate materials and material to be treated. Pilot-testing must be conducted to clearly define performance and versatility. Pilot treatment systems, done on a laboratory bench scale, may be sufficient to at least generally define treatment potential and efficiency.

The question of the range of environments where a stable biological environment can be maintained must be studied over longer treatment periods. The availability of sites to determine process longevity under a variety of conditions is limited. There are limited naturally occurring parallel situations that illustrate a stable biological isolation.

Forming a barrier around the individual metal sulfides contributing particles or precipitation of metals in an insoluble form achieves isolation/remediation goals. A detailed understanding the hydrology of the site is required to achieved successful results when using noninvasive options. Flow characteristics and in situ conditions dictate the costs and operational practicality of the utilization of in situ biological source treatment as an adequate control of the production of MIW. Observation and amendment distribution difficulties through wells and underground recharge of groundwater are the hurdles that affect the application of this technology, just as they affect the application of any in situ treatment technology.

5.

Performance

New research suggests that the addition of a carbon substrate may change

the microbial ecology to favor the formation of a microbial biomass that

forms the biofilm. The biofilm has been shown to isolate the pyrite from

the oxygen in the adjacent water, therefore preventing oxidation (Jin et

al. 2008a). Robinson-Lora and Brennan (2009a, 2009b) studied complex substrates

that combine both chemically active components and biological components

to chemically buffer systems and biologically establish and maintain anaerobic

conditions.

Recent advances in the manipulation of aquifers to promote bioremediation have led to the use of various organic substrates to establish and maintain anaerobic conditions suitable to long-term subaqueous disposal. The biological process, known as “controlled saprobization,” uses microbial populations to create alkalinity to essentially reverse the acidification process (Totsche, Fyson, and Steinberg 2006).

Isolation by chemically or biologically created barriers between the mine waste and groundwater is still considered a new and innovative treatment option. The cost of the isolating material is critical, as is access to the contamination source. The ability to minimize the spread of MIW contamination by avoiding incremental acidification of additional groundwater is the goal of the treatment. Acidification of groundwater that then travels into previously unaffected materials is a nebulous impact that is undoubtedly critical at many sites. In general, in situ methods are the least disruptive and can be a cost-effective option for managing MIW production.

The success of an in situ biological source treatment system relies on site specific conditions. The Sequatchie Valley Coal Mine Case Study indicates that the in situ biological source treatment systems hold significant promise. The treatment of the Sequatchie Valley Coal Mine near Dunlap, TN is still functioning as expected over operating periods of about two years.6. Costs

Relative to active treatment technologies, in situ biological source treatment

systems can be an inexpensive way to reduce MIW discharges. Costs factors

include mobilization and use of heavy equipment at remote and or steep

sites, local availability and quality of the inoculum and substrate required

for treatment, the potential need for operation in extreme cold conditions,

and the site-specific longevity of the treatment effectiveness.

7. Regulatory Considerations

Construction of in situ biological source treatment systems may require

approvals and/or permits from one or more regulatory authorities (federal,

state, and/or local) depending on the site location and the applications

being proposed.

Sewage and some carbon substrates (materials being used for treatment) may be considered pollutants. The release of these materials to the subsurface may be regulated; however, EPA has clarified the use of injectants to treat contamination in groundwater (see www.itrcweb.org/Documents/RCRA3020andLTR.pdf).

Projects may have to deal with one or more of the following acts or agencies:

- Clean Water Act

- Comprehensive Environmental Response Compensation, and Liability Act

- Surface Mining Control and Reclamation Act

- U.S. Environmental Protection Agency

- state environmental agencies

- local county or municipal governments

8. Stakeholder Considerations

Because of their simple construction, limited operation and maintenance

requirements, and generally minor post-construction surface visual impacts,

in situ biological source treatment systems may not suffer from many of the

stakeholder issues that may apply to other MIW treatment technologies. However,

project and site specific stakeholder considerations should be considered

when selecting and designing a treatment system.

Finally, it is important to mention that the case study reported encountering no public issues or concerns with in situ biological source treatment system projects.

9. Lessons Learned

A complete analysis of the MIW and the treatment material, including seasonal

and formulation variations, must be completed before selecting an in situ

biological source treatment system. Bench-scale tests exploring variations

in the treatment material and the material to be treated are invaluable when

determining whether or not an in situ biological source treatment system

is applicable and what type of treatment material is suitable for the site.

Table 10-1. Case study using in situ biological treatment

11. References

Bond, P. L., G. K. Druschel, and J. F. Banfield.

2000. “Comparison of Acid Mine Drainage Microbial Communities in Physically

and Geochemically Distinct Ecosystems,” Applied and Environmental Microbiology 66(11):

4962–71.

Daubert, L. N., R. A. Brennan. 2007. “Passive Remediation of Acid Mine Drainage Using Crab Shell Chitin,” Environmental Engineering and Science 24(10): 1475–80.

Jin, S., P. H. Fahlgren, J. M. Morris, and J. S. Cooper. 2008a. “Source Treatment of Acid Mine Drainage at a Backfilled Coal Mine Using Remote Sensing and Biochemistry,” Water and Air Pollution 188: 205–12.

Jin, S., P. H. Fahlgren, J. M. Morris, and R. B. Gossard. 2008b. “Biological Source Treatment of Acid Mine Drainage Using Microbial and Substrate Amendments: Microcosm Studies,” Mine Water and the Environment 27(1): 20–30.

Maclean, L. C. W., T. J. Pra, T. C. Onstott, and G. Southam. 2005. High-Resolution Structural and Chemical Studies of Framboidal Pyrite Formed Within a Bacterial Biofilm. Princeton University, Department of Geosciences.

Robinson-Lora, M. A., and R. A. Brennan. 2009a. “Efficient Metal Removal and Neutralization of Acid Mine Drainage by Crab-Shell Chitin Under Batch and Continuous-Flow Conditions,” Bioresource Technology 100(21): 5063–71.

Robinson-Lora, M. A., and R. A. Brennan. 2009b. “The Use of Crab-Shell Chitin for Biological Denitrification: Batch and Column Tests,” Bioresource Technology 100(2): 534–41.

Totsche, O., A. Fyson, and C. E. W. Steinberg. 2006. “Microbial Alkalinity Production to Prevent Reacidification of Neutralized Mining Lakes,” Mine Water and the Environment 25(4): 204–13.