Case Study as part of a Web-based

Technical and Regulatory Guidance

Magmont Mine Site

Iron County, Missouri

1. Site Information

1.1 Contacts

Bill Zeaman

Missouri Department of Natural Resources

1101 Riverside Drive

Jefferson City, MO 65101

Telephone: 573-751-1312

E-mail: [email protected]

1.2 Name, Location, and Description

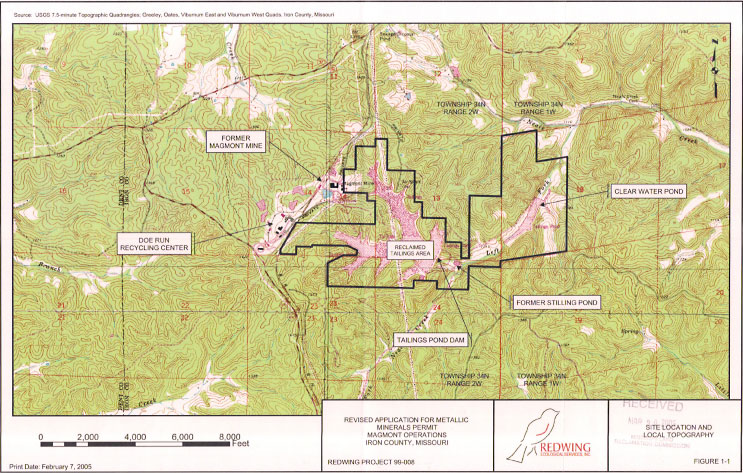

The Magmont Mine Site (Site) is located about 1.5 miles south of Bixby,

Missouri, within the northern third of the Viburnum Trend (Figure 1-1). First

intersected by surface drilling in September 1962, the Magmont orebody was

outlined by about 200 drill holes. Cominco American’s Magmont mine began

production in 1968 and ceased in May 1994 with a total of 26 million

tons of ore mined during operation. The room and pillar trackless method

of mining was used, and all ore was beneficiated in the Magmont mill where

separate lead, zinc, and copper concentrates were produced. The concentrates

were processed off site.

Figure 1-1. Map of the Magmont Mine site.

During the beneficiation process, 940,000 tons of waste material (tailings) was produced annually. The waste material ranged in size from fine silt to fine sand particles. In 1988, the tailings material was composed of 0.15% lead, 0.13% zinc, and 0.88% copper by weight. It also contained 30%–35% solids, with the remainder as water.

The Magmont Operations tailings facility was composed of the main tailings pond and dam, a spillway located south of the tailings pond dam, a small stilling pool located downstream of the tailings pond dam, and a clear water pond located downstream of the stilling pool. The tailings were deposited during dam construction using the downstream method, with the coarse tailings fraction being deposited in the pond near the downstream dam face and the fine fraction settling farther back in the reservoir. A cyclone was used to separate the fine and coarse fractions at the crest of the dam. During operations, the tailings were deposited throughout the impoundment. The ultimate surface area of the tailings pond and waste management area is calculated to be 293 acres with lead tailings that on average are 60 feet deep. Pumping of mine water to the tailings pond continued until May 1995.

Nearly 30 years of lead mining has affected soil, surface water and sediment, and groundwater in the area. The mine is currently the only lead producer in closure in Missouri under the Missouri Metallic Minerals Waste Management Act.

2. Remedial Action and Technologies

Reclamation of the site is regulated under the Missouri Metallic Minerals

Waste Management Act (MMWMA) and the Clean Water Act. As required by the

MMWMA, a Closure Plan was developed that provides a mechanism to contain

metallic mineral wastes on site, ensure the integrity of waste management

structures, and achieve the designated final uses of the MMWMA. The site

has been reclaimed through a combination of grading, capping, surface water

control measures, and revegetation.

As part of the reclamation, the tailings material was capped with 2–6 feet of clay material extracted from nearby hills surrounding the site. The soil from the adjacent side slopes is characterized as Clarksvillle very cherty silt loam with a moderately rapid permeability in the upper profile (2.0–6.0 inches per hour) to moderate permeability in the lower profile (0.6–2.0 inches per hour). The permeability of these soils allows for adequate infiltration of water into the covered tailings further minimizing runoff. Following placement of the soil, the surface of the tailings pond was disked, seeded, and fertilized. The planted vegetation was selected to establish a vegetative cover that is diverse, effective, permanent, capable of stabilizing the surface from wind and water erosion. Reclamation seeding was accomplished between 1992 and 1999. The mix of species planted included warm-season grasses, legumes and cool-season grasses, and woody vegetation (Figure 2-1). In addition to seeding, revegetation activities included annual applications of fertilizer and one controlled burn in 1998.

Figure 2-1. A reclaimed tailings impoundment at Magmont Mine.

Drainage swales were constructed to direct surface-water flow across the site and minimize standing water on the tailings materials. The swales are useful in decreasing surface-water infiltration through the tailings. Rip-rap was installed along a northern drainage channel to preclude potential erosion during large rainfall or snow melt events. Grading activities undertaken to promote positive drainage with the waste management area have eliminated the majority of the open water areas of the site. A total of five open water areas, totaling 39 acres, remain.

During operation of the Magmont facility, a portion of the ore concentrated was shipped on trucks to various smelters. Six spill sites were identified where trucks carrying lead and copper concentrated overturned. Those six sites were remediated by excavating approximately 4,850 cubic yards of contaminated material and depositing the material in a 2.5-acre repository in a portion of the tailings area. The excavated material had an average lead content of 1,550 mg/kg. Once all the excavated material was placed in the repository, the material was graded to a maximum thickness of 2 feet, covered with stockpiled soil removed prior to the placement of the spill site material, covered with an additional 6 inches of topsoil, and contoured to provide positive drainage. The disturbed area was then seeded with an approved seed mixture and mulched with straw.

A groundwater monitoring system, including a background monitoring well and five downgradient monitoring wells, was installed at the site in 1991. The monitoring wells are sampled quarterly to ensure protection of the groundwater from trace contaminants in the tailings.

The main tailings dam, which is 135 feet high and has a reservoir storage volume of 12,500 acre-feet of tailings and water, is regulated under the Missouri Dam Safety law. The stilling pond located immediately downstream of the dam allowed fines in water discharging from the dam to settle out of the water before joining the main stream during operations. The stilling pond was filled and vegetated during reclamation activities. Routine inspections of the tailings dam are conducted every two years.3.

Performance

Vegetation monitoring was initiated in the fall of 1998 and has been conducted

annually since that time. Quantitative monitoring included sampling of

overall vegetative cover and cover of individual species present in permanent

1 m square pots. Vegetation monitoring also included qualitative visual

observation of side slopes, above and outside the tailings areas, and on

tailing structures. The revegetation effort will be considered successful

if in any given area the data indicate that there is an average of at least

80% cover in two consecutive monitoring periods in two consecutive years.

Further, although species information is being collected and reported,

it will not be directly tied to success criteria.

Surface water quality and flow was monitored quarterly from 1988 to 1993 and has been monitored monthly since 1993 in accordance with the site National Pollutant Discharge Elimination System (NPDES) discharge permit. The surface water sampling network consists of two permitted outfalls and one regulated sampling point. The water quality parameters monitored include nonfilterable residue, lead, copper, zinc, cadmium, mercury, oil and grease, and pH. Table 3-1 summarizes average surface water quality parameters for the NPDES Outfalls from March 1993 to June 1995 (pre-1995) and June 1995 to December 2006 (post-1995).

Table 3-1. Surface water quality monitoring results

Parameter |

Monthly

Average Permit Limit #001 |

#001 Average (mg/L) |

Monthly

Average Permit Limit #003 |

#003 Average (mg/L) |

||

| Pre-1995 | Post-1995 | Pre-1995 |

Post-1995 |

|||

| Non-Filterable Residue | 20 |

5.42 |

2.10 |

* |

* |

* |

| Lead | 0.3 |

0.020 |

0.0006 |

0.029 |

0.009 |

0.006 |

| Zinc | 0.5 |

0.260 |

0.048 |

0.440 |

0.139 |

0.032 |

| Copper | 0.15 |

0.0076 |

0.0052 |

0.037 |

0.0062 |

0.0055 |

| Cadmium | 0.05 |

0.007 |

0.005 |

* |

* |

* |

| Mercury | 0.001 |

0.0002 |

0.0002 |

* |

* |

* |

| Oil & Grease | 10 |

2.404 |

5.210 |

* |

* |

* |

| pH | 6–9 |

7.96 |

7.87 |

6-9 |

8.07 |

8.04 |

Note: averages calculated using detection limit values for non-detect results *Not required by NPDES permit Outfall #002 is being transferred to Doe Run |

Groundwater quality samples have been collected from available monitoring

wells since March 1992. Initially groundwater samples were analyzed for the

following parameters: total and dissolved metals (antimony, arsenic, barium,

boron, cadmium, calcium, chromium, cobalt, copper, iron, lead, magnesium,

manganese, mercury, nickel, potassium, selenium, silver, sodium, thallium,

and zinc) and major ions and general chemistry (bicarbonate, carbonate, bromide,

chloride, conductivity, fluoride, total dissolved solids, hardness, nitrogen-ammonia,

nitrate-nitrogen, nitrite-nitrogen, pH, sulfate, and total suspended solids).

Beginning in October 1997, and continuing to date, sampling has focused on

total and dissolved lead, cadmium, manganese, iron, and zinc, copper, and

silver.

Table 3-2. Inspection and maintenance plan summary

Activity |

Initial |

Initial |

Reevaluation of frequency and duration |

Comments |

Preclosure/post closure surface water monitoring

|

|

|

|

|

Groundwater monitoring

|

Semiannual |

5 years |

At 5 years, quarterly for 2 years following permit re-issuance, then semi-annual for remaining 3 years of permit |

Continue as needed, if impacts from tailings are detected at concentrations above water quality criteria. Re-evaluate constituents of concern for possible delisting based on accumulated data. |

Reclamation

|

1 time |

Following tailings pond dewatering |

During facility inspection

and maintenance |

Reseed as needed per monitoring

results. |

Spillway and dam inspection and maintenance

|

|

|

|

|

Review of inspection maintenance plan |

5 years |

|

Every 5 years |

Continue as needed pending achievement of closure requirements for two consecutive years. |

4. Costs

None reported.

5. Regulatory Challenges

None reported.

6. Stakeholder Challenges

The public is not allowed to participate in the permitting process.

7. Other

Challenges and Lessons Learned

In retrospect, it would have been preferable to have stockpiled soil to use

as cover instead of robbing soil from the adjacent hillside.

8. References

Clausen, R. S., and R. L. Thomas. 2007. “Revised Application for Metallic

Minerals Waste Management Permit No. MM-006, Teck Cominco American Incorporated,

Magmont Operations, Bixby, Missouri.” Submitted to Missouri Department of

Natural Resources, Division of Environmental Quality, Land Reclamation Program.

Prepared by Redwing Ecological Services, Inc.