Case Study as part of a Web-based

Technical and Regulatory Guidance

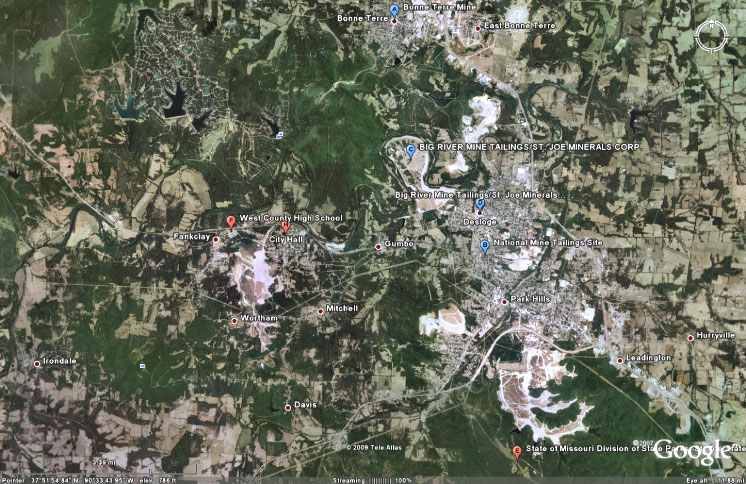

Big River Mine Tailings Site

St. Francois County, Missouri

1. Site Information

1.1 Contacts

Greg Bach

Missouri Department of Natural Resources

1730 East Elm Street

Jefferson City, MO 65101

Telephone: 573-431-5322

E-mail: [email protected]

Jason Gunter

Environmental Protection Agency Region 7

901 North Fifth Street

Kansas City, KS 66101

Telephone: 913-551-7358

E-mail: [email protected]

1.2 Name, Location, and Description

The

Big River Mine Tailings/St. Joe Minerals Corp. site is located in Desloge,

in a former mining region of southeast Missouri known as the “Old Lead Belt.”

This site comprises six large areas of mine waste in this rural region, approximately

110 square miles in size (Figure 1-1). The areas included are the Bonne Terre

Mine Tailings Site, the Leadwood Mine Tailings Site, the Elvins Mine Tailings

Site, the Federal Mine Tailings Site, the Desloge Mine Tailings Site, and

the National Mine Tailings Site. Also included are the surrounding residential

and recreational areas.

Figure 1-1. Aerial view of the Big River Mine site.

Mining in the area began in the mid-1700s and peaked in 1942 when 197,430 tons of lead was produced. Mining in the area ended in 1972. Approximately 250 million tons of tailings and chat (solid mine waste) was produced from local mills during this time. The residual lead content in the tailings material is about 0.5%; other minerals such as cadmium and zinc are also present. In 1977, heavy rains caused an estimated 50,000 cubic yards of tailings to slump into the Big River. Surface water and various forms of biota in the Big River contain elevated concentrations of lead. Fish in the Big River have shown elevated levels of lead. The state of Missouri advises people not to eat fish from the Big River downstream of this site. In addition, dust created by wind erosion of the mine waste piles contaminates the surrounding area and is a potential hazard to residents. A 1997 human health exposure study by the Missouri Department of Health showed that 17% of the children under seven years old had blood-lead concentrations exceeding the health-based standard of 10 mg/dL.

2. Remedial Action and Technologies

Considering the large volume of solid mine waste left at the site, capping,

covers, and grading represent the most feasible and effective remedial action.

Work begins with a detailed engineering analysis to determine the geotechnical

characteristics (including seismic analysis), concentration of metals, and

local hydrology. Grading specifications are then developed based on the results

of the analysis. Cover material generally consists of blasted, crushed, screened

quarry rock and cover soil. These materials are placed on the solid mine

waste based on the specifications of the engineering design. Generally, rock

is placed on slopes steeper than 4H:1V, and soil is used to cover flat areas.

Seeding of the soil areas ensures the long-term stability of the soils. In

some areas of the site, direct vegetation of solid mine waste will provide

an effective cover. However, the solid mine waste is nutrient poor and requires

a substantial amount of soil amendments to build an organic layer capable

of supporting vegetation.

3. Performance

Effectiveness of the caps and covers are evaluated with regular water sampling

and ambient air monitoring. Water samples are collected both upstream of

and downstream of the site discharge points. Ambient air monitors measure

both lead and dust blowing from the site. Comparison of these results to

the action levels allows for some measurement of success. Additionally, routine

inspections of remediate areas of the site are required to ensure that the

caps and covers remain in place and are not compromised in any way.

4. Costs

Cost of capping, covers, and grading at the site vary depending on specific

conditions at each solid mine waste area. Previous actions range in costs

from $7,000/acre to $95,000/acre with an average cost of $20,000/acre.

Cost of activities at these site are reported as a total:

- Capital: Varies based on specific site conditions.

- Operation and maintenance: Varies based on type of cap or cover.

5. Regulatory

Challenges

Leaving large quantities of solid mine waste in place on site present issues

with long-term stewardship (LTS). LTS can include the use of restrictive

and/or environmental covenants and implementation of a monitoring and maintenance

plan. Restricting site access or allowing continued use of the site for recreational

or industrial purposes poses a unique set of challenges. Due to the size

of these mine waste sites, it is often not feasible to fence or otherwise

block access to the site. Many members of the community do not recognize

that the sites are private property and trespass frequently. Resources are

not available to police to enforce trespassing laws. Off-road vehicular traffic

is of particular concern as the designs of most caps are not intended for

this type of use. In some cases, the final design of the cap is intended

for future use as a recreation area or as an industrial site. Monitoring

and maintenance become the primary regulatory challenge in these instances.

6. Stakeholder Challenges

No information available

7. Other Challenges and Lessons Learned

The Doe Run Company uses biosolids (treated sewage sludge) to increase the

organic matter and nutrients of the mining areas for the establishment of

vegetation. The establishment of vegetation on the tailings areas reduces

the amount of lead-contaminated dust blowing off the piles, which is vital

to the remedy. The biosolids are tested for hazardous substances and applied

at agronomic rates in areas of the piles not susceptible to runoff. The biosolids

provide the substances necessary for vegetation to grow in the nutrient poor

conditions of the tailings; however, public perception over biosolids treatment

has been an ongoing concern. Although the biosolids are being applied in

a safe and legal manner, some members of the public near these piles feel

that the treatment is unnecessary.

8. References

Barr Engineering Company. 2009. Engineering Evaluation/Cost Analysis

Report—Federal Mine Tailings Site, Park Hills, Missouri (draft). Prepared

for the Doe Run Company.

NewFields, Inc. 2006. Focused Remedial Investigation for Mined Areas in St. Francois County, Missouri. Prepared for the Doe Run Company.

U.S. Environmental Protection Agency. 2005. Engineering Evaluation/Cost Analysis Report for National Mine Tailings Site, Park Hills, Missouri. Prepared by Black and Veatch.