Case Study as part of a Web-based

Technical and Regulatory Guidance

Leviathan Mine Site

Alpine County, California

1. Site Information

1.1 Contacts

Timothy Tsukamoto, Ph.D.

Ionic Water Technologies

Telephone: 775-321-8101

Chein Kao

California Water Board

Telephone: 530-542-5461

E-mail: [email protected]

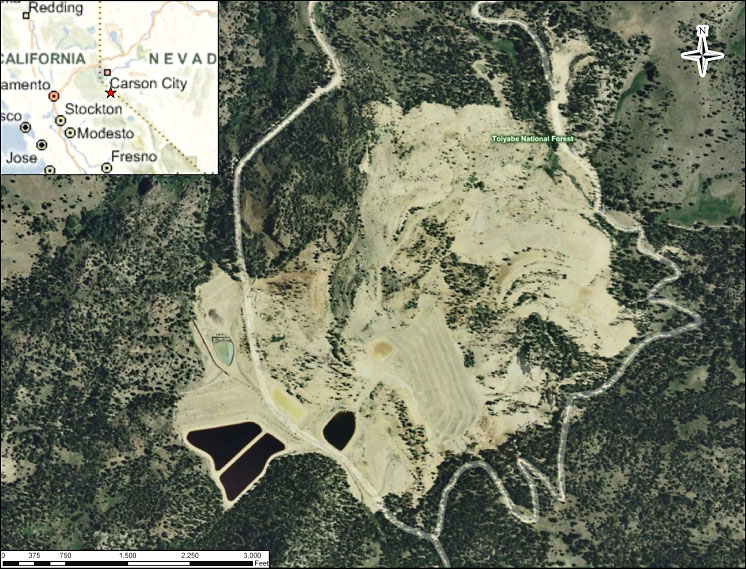

1.2 Name, Location, and Description

The Leviathan Mine is a former sulfur mine that the state of California

acquired in the early 1980s to address water quality problems caused by historic

mining. The open-pit mine was a source of sulfur from the 1860s to the 1960s

and is now inactive. The Leviathan Mine site is at an elevation of 7500 feet

above sea level, on the eastern flank of the central Sierra Nevada Mountains

in Alpine County, California, approximately 6 miles east of Markleeville,

California, and 5 miles west of Topaz Lake, Nevada (Figure 1-1).

Figure 1-1. Aerial view of the Leviathan Mine.

Created with ESRI ArcView software using Microsoft Bing maps.

The Leviathan Mine encompasses 32 patented mineral claims and a patented mill site, which together total 656.09 acres. The state-owned portion of the site encompasses 475.70 acres; mining disturbance is evident on approximately 231 acres. The majority of mining disturbance is on state-owned property, with approximately 21 acres of disturbance found on property owned by the U.S. Forest Service Humboldt-Toiyabe National Forest. The affected media include soil, sediment, surface water (e.g., stream, rivers, runoff, and drainage), surface pool water (e.g., lakes, ponds, and pools), and groundwater.

2. Remedial Action and Technologies

Acid mine drainage overflows the containment ponds on site during high

spring runoff conditions at a rate of 30–300 gallons per minute. The overflow

contains acidity and high concentrations of sulfate and metals, including

aluminum, arsenic, cadmium, copper, iron, nickel, selenium, and zinc. Manganese

is a secondary contaminant.

Under the authority of the Comprehensive Environmental Response, Compensation and Liability Act, the overflow water is treated by chemical precipitation to mitigate human health and ecological risks. The full-scale treatment process, used seasonally since 2005, includes lime neutralization, aeration, and oxidation of reducing metals with the rotating cylinder treatment system (RCTS) system. The quantity being treated ranges between 3 million and 20 million gallons annually.

3. Performance

Performance criteria include measuring the contaminant concentrations

in the effluent water discharged to Leviathan Creek to ensure compliance

with Environmental Protection Agency and state of California regulatory

objectives. These include the following USEPA Discharge Criteria 2008 Work

Plan for Leviathan Mine Alpine County, California Water Quality Parameter

Maximums: average pH 6.0–9.0; arsenic (dissolved) 0.34 mg/L (0.15 mg/L);

aluminum (dissolved) 4.0 mg/L (2.0 mg/L); cadmium (dissolved) 0.009 mg/L

(0.004 mg/L); chromium (dissolved) 0.97 mg/L (0.31 mg/L); copper (dissolved)

0.026 mg/L (0.016 mg/L); iron (dissolved) 2.0 mg/L (1.0 mg/L); lead (dissolved)

0.136 mg/L (0.005 mg/L); nickel (dissolved) 0.84 mg/L (0.094 mg/L); selenium

(total recoverable) not promulgated (0.005 mg/L); zinc (dissolved) 0.21

mg/L (0.21 mg/L).

Notes:

- pH measurement based on 24-hour average discharge.

- Concentrations based on a daily grab samples, each grab sample field-filtered and acid-fixed promptly after collection.

- Concentrations based on four daily grab samples, each grab sample field-filtered and acid-fixed promptly after collection.

4. Costs

The capital cost of the RCTS system was less than $100,000. The cost of

operation and maintenance depends on the volume of water treated each season.

Overall treatment cost of all technologies applied at the Leviathan

site is reported as follows:

- Capital: $5 million

- Operation and maintenance: $2 million annually.

- Unpredictable amounts of acid mine drainage from year to year make budgeting and contracting processes very uncertain.

5. Regulatory Challenges

None encountered.

6. Stakeholder Challenges

No information available.

7. Other Challenges and Lessons Learned

The RCTS system was quickly mobilized and operated at a time of year unachievable

with most lime precipitation systems. The small footprint of the system allowed

it to be mobilized using standard pickup trucks. On-site engineering was

not required for the placement of the system. Power requirements are reported

to be “minimal.” Unpredictable amounts of acid mine drainage from year to

year make budgeting and contracting processes very uncertain.

8. References

No information available.