Case Study as part of a Web-based

Technical and Regulatory Guidance

Tar Creek Superfund Site

Ottawa, Oklahoma

1. Site Information

1.1 Contacts

Oklahoma Department of Environmental Quality

Land Protection Division

Tar Creek Section

Contacts: Angela Hughes, Dennis Datin, or David Cates

Telephone: 405-702-5100

USEPA Region VI Remedial Project Managers:

Bob Sullivan, 214-665-2223

Ursula Lennox, 214-665-6743

Gary Baumgarten, 214-665-6749

USEPA

John Meyer (submitted separate case study for same site)

Telephone: 214-665-6742

E-mail: [email protected]

1.2 Name, Location, and Description

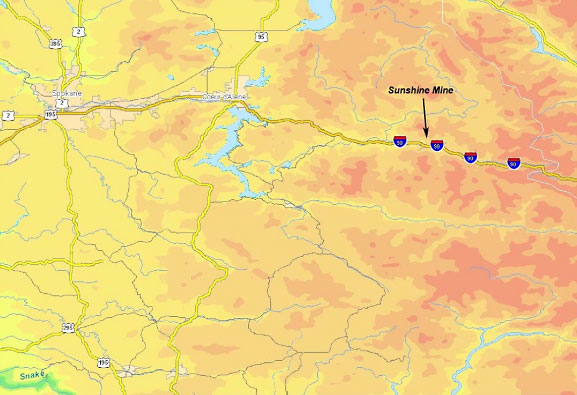

The Tar Creek Superfund Site is located in

Ottawa County, Oklahoma (latitude 36.99538N, longitude 94.82852W) and is part

of a former lead and zinc mining area that operated from the early 1900s through

1970. The site is part of the Tri-State Mining District located at the junction

of northeast Oklahoma, southeast Kansas, and southwest Missouri (Figure 1-1).

The site has no clearly defined boundaries but consists of the areas of Ottawa

County impacted by mining waste (approximately 40 square miles mainly in sections

of T29N R23E). The principal site communities include Cardin, Commerce, North

Miami, Picher, and Quapaw. Approximately 19,556 people live in the mining area

and in communities in proximity to the mining area.

Figure 1-1. Map of the Tar Creek Superfund site area. Created with ArcGIS Desktop Version: 9.3.1

Mining here consisted of underground room-and-pillar mines with dewatering about 200 ft below land surface. Water filled the mines after abandonment, and the acid mine water that formed in the approximately 100,000-acre-foot mine pool began discharging into surface waters in 1980.

At the Tar Creek Superfund site, the primary impacts are from heavy metals, including cadmium, lead, and zinc. Reclamation of the site falls under the provisions of the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA). The primary treatment technology in place at the site is chat sales and backfilling/subaqueous disposal to treat approximately 50,000,000 cubic yards of material.

Ore production consisted of crushing and grinding the rock to standard sizes and separating the ore. Ore processing was accomplished in either a dry gravity separation or through a wet washing or flotation separation. Dry processes produced a fine gravel waste commonly called “chat.” The resulting waste rock, chat, is composed of mainly chert with minor amounts of limestone and dolomite, with particle sizes ranging from 9.51 mm to less than 0.075 mm, with most of the mass in the coarser sizes. The wet processes resulted in the creation of tailings ponds used to dispose of waste material after ore separation. The wastes from wet separation are typically sand and silt size called “tailings.” A lesser-occurring type of mine waste is called development rock. Development rock is the waste rock generated in drilling shafts to the deep mines and therefore did not come from the major ore-producing rocks. Typically, development rock consists of large boulders.

Mine and mill wastes are located throughout the site. Processing of the lead and zinc sulfide ores occurred at mills located about every 40 acres (due to leasing requirements of the Native American–owned lands) and resulted in many large piles of chat covering the approximately 40 square mile superfund site. Some areas have chat waste piles up to 200 feet high. Much of the original chat volume is gone due to its use as aggregate in asphalt and concrete, gravel for roads, rock metal for railroads, and general fill material. About 35 million cubic yards of chat remains to be dealt with at the site.

Other areas of the site include agricultural or residential properties. Mine and mill wastes are typically located adjacent to the former mines, which are concentrated near the town of Picher but are also scattered throughout the rest of Ottawa County.

Affected media include soil, sediment, surface water (e.g., stream, rivers, runoff, and drainage), and groundwater. Despite remedial actions, the surface water and shallow groundwater remain contaminated at circumneutral pH with relatively high iron, sulfate, zinc, cadmium, lead, hardness, and total dissolved solids. The areas main source of drinking water comes from groundwater aquifer below the mine pool.

The recent record of decision (ROD) for Operating Unit (OU4) (USEPA 2008) authorizes continued chat sales (reuse) as part of the remedy. An estimated 29,231,000 cubic yards of chat could be used for environmentally acceptable applications. The ROD limits chat sales to only those environmentally safe uses defined in the Chat Rule, its preamble, and the ROD, as (1) transportation uses including (a) asphalt concrete, slurry seals, microsurfacing or in epoxy seals and (b) portand cement, flowable fill, stabilized base, chip seal, or road base, providing on a case-by-case basis the material passes either (i) an SPLP test or (ii) a site-specific risk assessment; and (2) nontransportation applications used in cement and concrete (nonresidential) construction projects and use in applications that encapsulate the chat as a material for manufacturing a safe product or as part of an industrial process (e.g., glass, glass recycling) where all waste by-products are properly disposed, described in EPA’s June 2007 Tar Creek fact sheet.

2. Remedial Action and Technologies

At the Tar Creek Superfund Site, the primary impacts are from heavy metals,

including cadmium, lead, and zinc. Reclamation of the site falls under the

provisions of the Comprehensive Environmental Response, Compensation, and

Liability Act (CERCLA). The primary treatment technology in place at the

site is reuse through chat sales to deal with approximately 35 million cubic

yards of chat. Approximately 13 million cubic yards of chat scattered in

the perimeter areas of the site will be excavated to native soil and transferred

(hauled) to a nearby chat pile, where active chat processing is occurring

or will occur in the future. Thus, private industry (chat-processing companies)

will process and sell the chat (approximately 35 million cubic yards) for

profit following the environmentally safe applications for reuse defined

in the Chat Rule and the OU4 ROD. Reuse technology through chat sales is

expected to continue for 30 years. Site cleanup goals are based upon the

mitigation of human health risk and mitigation of ecological risk.

Backfilling/subaqueous disposal at the site consists of excavation and formation of a tailings slurry with water, then injecting the slurry under gravity flow back into the existing mine workings approximately 200 ft beneath the ground surface. This treatment technology has been operating as a pilot for approximately three years and is expected to continue for 30 years.

3. Performance

Performance criteria include the elimination of direct contact by removing

impacted surface material. The objectives of chat reuse are to reduce exposures

of lead cadmium and zinc to human health and the environment. In this regard

the remedial action objectives for source materials (e.g., chat) are zero

discharges from source materials to surface water. The criteria for soils

underlying the source material are 500 ppm for lead for protection of human

health and 10 mg/kg cadmium and 1100 mg/kg zinc for the protection of

terrestrial fauna. The specific criteria for chat reuse applicable to the

SPLP tests or risk assessments are the National Primary Drinking water standards

(MCLs) for lead (15 µg/L) and cadmium (5 µg/L) in potential drinking water

sources and freshwater chronic National Recommended Water Quality Criterion

(WQC) for zinc of 120 µg/L.

4. Costs

Capital: Since the chat processors are private companies

conducting the business of chat sales, there is no cleanup cost associated

with this project. The cleanup cost associated with chat sales (reuse) is

related to excavation of chat pile bases to native soil in the perimeter

areas of the site (estimated to be 13,194,000 cubic yards of chat covering

2,100 acres) and transporting (releasing) this material to a nearby chat

pile, where active (or future) chat-processing operations exist or will exist.

Total Direct Capital Cost (DCC): $63,463,140 (excavate, load, haul, and place 13,194,000 cubic yards of chat 12-mile round trip at $4.81/yd3) plus $6,226,500 (clear and grub, deep till, amend soils, and revegetate 2,100 acres at $2,965/acre). This cost equates to $2.38/yd3 of chat used for environmentally safe reuse (29,231,000 yd3). These costs do not include indirect capital costs associated with development of IC program: $500,000; management (5% of DCC): $3,484,482; remedial design (5% of DCC): $3,484,482; Construction oversight and management (6% of DCC): $4,181,378; technical support (2% of DCC): $1,393,793; and contingencies (20% of DCC): $13,937,928, totaling $26,982,063 or another $0.92/yd3 for environmentally safe reuse of chat (29,231,000 yd3).

Operation and maintenance: $375,000 per year times 30 years = $11,250,000 (administer landowner agreements, institutional controls, and vegetation management) or $0.38/yd3 for environmentally safe reuse of chat (29,231,000 yd3).

5. Regulatory Challenges

It appears that the threat of incurring future CERCLA liability may have

caused reduced reuse of chat. With the passing of the Chat Rule (40 CFR Part

278) and the signing of the Tar Creek ROD for OU4 (USEPA 2008)

that together identify environmentally safe uses for chat (albeit a limited

number of uses), this threat should be reduced and chat sales should increase.

The federal rule (40 CFR Part 278) was enacted to identify criteria for environmentally

safe reuse of chat.

The state is responsible of institutional controls, including deed notices and maintenance of repository caps. The state is required to regulate the chat-processing facilities under applicable environmental laws.

6.

Stakeholder Challenges

Residents living downstream from the site expressed concern that placing

the material back into the mine workings would impact groundwater and surface

water. Another issue centered around relocation of the residents and potential

for mine-impacted waters to contaminate the underlying source of drinking

water, the Roubidoux. Additionally, there are issues related to chat ownership

and sales (i.e., most Native American owners of chat and some non–Native

American owners require payments for chat removed from their property when

EPA considers it a waste and has made no allowance for its purchase.)

7. Other Challenges and Lessons Learned

The ROD for Tar Creek OU4 may be too restrictive (too specific) concerning

the safe environmental uses for chat. It does not have a mechanism to determine

whether or not a future (nonspecified) use is safe.

8. References

USEPA (U.S. Environmental Protection Agency). 2007. “Criteria for the Safe

and Environmentally Protective Use of Granular Mine Tailings Known as Chat.”

40 CFR Part 278. https://projects.itrcweb.org/miningwaste-guidance/References/CFR-2008-title40-vol26-part278.pdf.

USEPA. 2008. “Record of Decision, Operable Unit 4, Chat Piles, Other Mine and Mill Waste, and Smelter Waste, Tar Creek Superfund Site, Ottawa County, Oklahoma, OKD980629844.” https://semspub.epa.gov/work/06/825746.pdf.