Case Study as part of a Web-based

Technical and Regulatory Guidance

Fort Hood Site

Killeen, Texas

1. Site Information

1.1 Contacts

Valentine Nzengung

PLANTECO Environmental Consultants, LLC

337 South Milledge Avenue, Suite 202

Athens, GA 30605

Telephone: 706-316-3525

http://www.planteco.com

1.2 Name, Location, and Description

New landfill located at Fort Hood, Texas.

2. Remedial Action and Technologies

To ensure the sustainable operation of a newly constructed landfill at Fort

Hood during its 30‑year projected operational life, the Department of the

Army needed sustainable technologies to treat metals that were the contaminants

of concern in the landfill leachate. A two-phase, engineered, green-treatment

approach consisting of a microbial mat bioreactor (MMB) and multiple, small,

containerized constructed treatment wetlands (CTWs) connected in series was

evaluated at the field pilot scale. The basic conceptual design relied on

the MMB to remove the bulk of the iron, manganese, and lead. The effluent

from the MMB then flowed into the CTWs to remove the boron as well as additional

iron, manganese, and lead. An oxidation/settling “pond” was included as the

final stage of the CTWs to “polish” the treated effluent before disposal

into the privately owned treatment works.

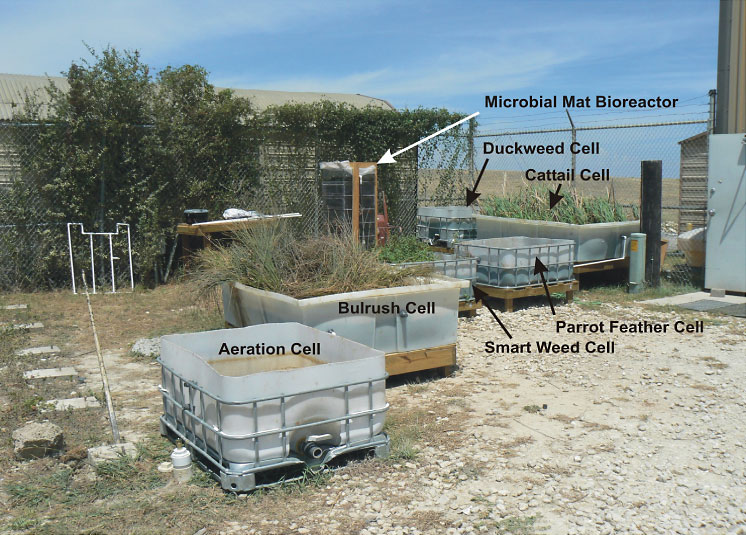

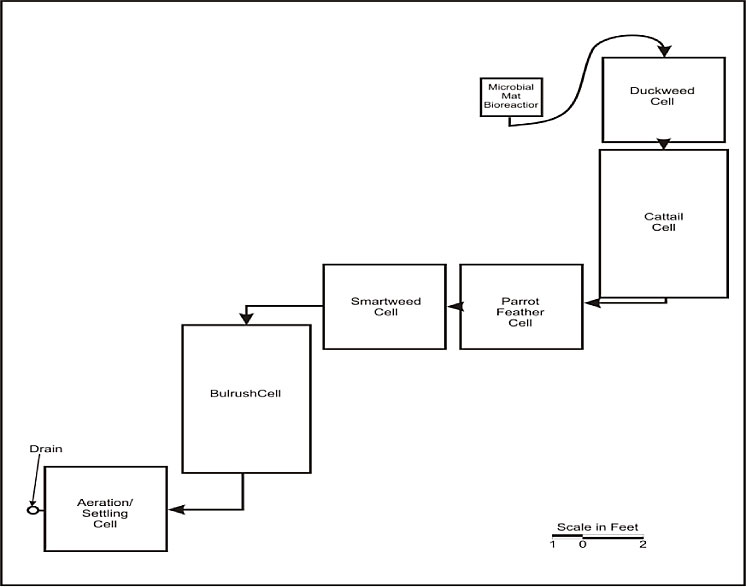

The final design used six CTW cells. Two large cells were 85" L × 56" W × 21" H, and four small cells were 48" L × 45" W × 22" H, for a total capacity of 535 gal:

Cell 1 (120 gal)—Duckweed (Lemnaceae)

Cell 2 (75 gal)—Cattails (Typha latifolia)

Cell 3 (120 gal)—Parrot feather (Myriophyllum aquaticum)

Cell 4 (35 gal)—Smartweed (Polygonum hydropiperoides)

Cell 5 (120 gal)—Bulrush (Scripus sp.)

Cell 6 (120 gal)—Aeration/settling

The smaller cells were enclosed in metal frames for support, and the larger did not have an external support frame. The CTW treatment train was set up as shown in Figures 2-1 and 2-2. Flow rates and residence times are shown in Table 2-1.

Figure 2-1. Technology design.

Figure 2-2. Technology overview.

Table 2-1. Flow data for pilot test

Parameter |

Microbial mat bioreactor |

Containerized constructed treatment

wetlands |

Flow rate in, gpm |

2 |

1 gpm |

Total volume treated, gal |

11,520 |

5,760 |

Residence time, minutes |

N/A |

535 |

Residence time, hours |

N/A |

8.9 |

The treatment

goals for the project were set as follows:

- Iron—Removal to <0.1 mg/L (1,000 mg/L)

- Boron—Removal to <0.5 mg/L (5,000 mg/L or 5 mg/L)

- All metals—≥80% removal

3. Performance

The MMB/CTW pilot test proved the viability of a modular MMB and CTW treatment

system for metals removal from water. The MMB performed quite well prior

to coating of the mat surface by undissolved iron precipitates. Even after

the mats were coated with the precipitates, the system was still able to

achieve some of the remediation goals.

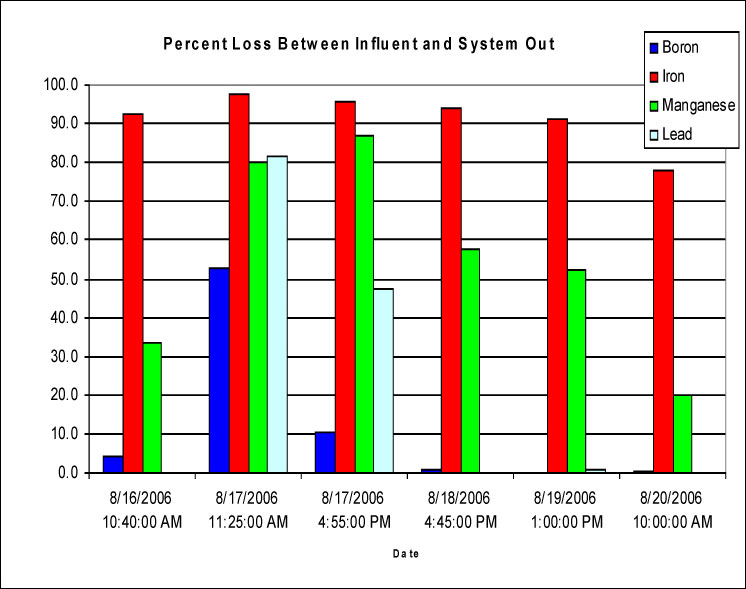

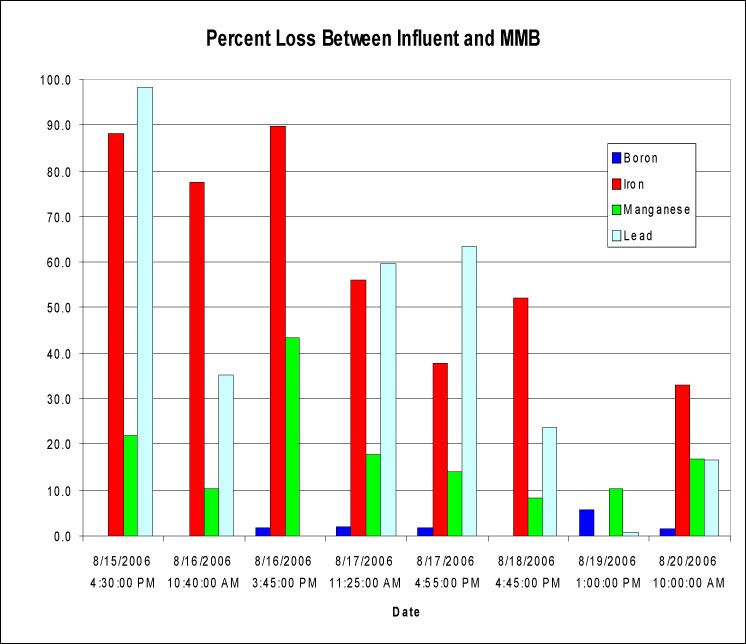

The influent iron concentrations in Fort Hood landfill leachate used in this pilot test varied widely 6,980–15,700 µg/L. Interpretation of the results of this pilot test was complicated by the fact that the influent concentration of the different metals in the untreated leachate was not consistent throughout the duration of the test. Specifically, the initial metal concentration varied with each batch of leachate supplied for treatment. Additionally, the concentration of some metals in some batches of the supplied leachate was low and below the treatment goal. Although the microbial mats were initially effective in removing >80% of the influent iron at a flow rate of 2 gpm, the bioactive mat surface was quickly overwhelmed by the deposit of precipitated iron in the influent leachate, which reduced the removal efficiency to <60% of the influent iron concentrations (Figures 3-1 and 3-2). Because the bioreactor was overwhelmed by the suspended iron, there were few microbial mat bioactive sites available for adsorption or precipitation of manganese, lead, or boron.

Figure 3-1. Loss of selected metals when comparing system influent and system effluent of the constructed treatment wetland.

(Negative values omitted for clarity.)

Figure 3-2. Percent loss of selected metals when comparing system influent and effluent of the microbial mat bioreactor.

(Negative values omitted for clarity.)

Overall the microbial mat bioreactor connected in series with the containerized treatment wetlands achieved the treatment goals (1,000 ppb) for iron. The boron levels in the landfill leachate were below the treatment goal, and so it is not possible to determine whether the MMB/CTW system can consistently remove boron to levels below the 5,000 µg/L treatment goal. The results of this pilot test highlight the need to install an iron precipitation and filtration step ahead of the modular microbial mat bioreactor. This goal can be easily accomplished by adding lime and sulfide to the influent landfill leachate and precipitating out the bulk of the iron. Pretreated landfill leachate, which contains little or no iron in suspension, should allow for optimum performance of the microbial mat bioactive surface.

A comparison of the treated effluent from the MMB and the CTW (Figures 3-1 and 3-2) indicates that the constructed treatment wetland was necessary to further remove some of the metals to the stringent compliance level. The treatment goals for iron (Table 3-1) were attainable by using the MMB alone.Table 3-1. Treatment goals for pilot phase

Contaminant |

Cleanup concentration |

Iron |

0.1 ppm |

Boron |

0.5 ppm |

All other metals |

80% removal |

4. Costs

- $1.35–$1.90 per 1000 gallons.

- Low concentrations (ppb) result in lower costs.

- Metals and higher contaminant concentrations result in higher costs.

5.

Regulatory Challenges

None encountered

6. Stakeholder Challenges

Use of treated water for irrigation water on training ranges needed regulatory

approval, which could be a lengthy process.

7. Other Challenges and Lessons

Learned

The field application of a technology developed at the bench scale encounters

a number of challenges when subjected to real-world conditions. The field-scale

demonstration of the passive treatment of landfill leachate using microbial

mats in series with multiple, containerized CTWs experienced a number of

challenges, including the following:

- The variability in landfill leachate composition from one batch to the other during the field test. This was especially problematic in estimating the percent metal removed given the 9 hours residence time and the fact that the influent and effluent (treated) samples were collected for analysis at the same time.

- The leachate was supersaturated with iron, resulting in an iron precipitate sludge in the bottom of the leachate holding tanks. The precipitate was pumped into the microbial mat bioreactor and overwhelmed the bioactive surface of the microbial mats, which significantly reduced the effectiveness of the microbial mats in removing the other metals present in the leachate at smaller concentrations.

- The irregular flow between the containerized wetlands connected in series. This was later found to be due to a blockage in one pipe at breakdown of the system.

- The low biochemical oxygen demand in the leachate did not promote mat growth, as was observed at the bench scale.

8. References

Bender, J., M. C. Duff, P. Phillips, and M. Hill.

2000. “Bioremediation and Bioreduction of Dissolved U(VI) by Microbial Mat

Consortium Supported on Silica Gel Particles,” Environmental Science

and Technology 34(15):

3235–41.

Bender, J., J. P. Gould, Y. Vatcharapijarn, and G. Saha. 1991. “Uptake, Transformation and Fixation of Se(VI) by a Mixed Selenium Tolerant Ecosystem,” Water, Air, and Soil Pollution 59(3–4): 359–67.

Bender, J., J. P. Gould, Y. Vatcharapijarn, S. Young, and P. Phillips. 1994a. “Removal of Zinc and Manganese from Contaminated Water with Cyanobacterial Mats,” Water Environmental Research 66(5): 679–83.

Bender, J., R. F. Lee, and P. Phillips. 1995. “A Review of the Uptake and Transformation of Metals and Metalloids by Microbial Mats and Their Use in Bioremediation,” Journal of Industrial Microbiology and Biotechnology 14(2): 113–18.

Bender, J., and P. Phillips. 1995. “Biological Remediation of Mixed Waste by Microbial Mats,” Federal Facilities Environmental Journal 6(3): 77–85.

Bender, J., J. R. Washington, B. Graves, P. Phillips, and G. Abotsi. 1994b. “Deposit of Zinc and Manganese in an Aqueous Environment Mediated by Microbial Mats,” Water, Air, and Soil Pollution 75(3-4): 195–204.

Hedin, R. S., R. W. Nairn, and R. L. P. Kleinmann. 1994. The Passive Treatment of Coal Mine Drainage. U.S. Bureau of Mines Information Circular 9389.

ITRC (Interstate Technology & Regulatory Council). 2003. Technical and Regulatory Guidance for Constructed Treatment Wetlands. Washington, D.C.: Interstate Technology & Regulatory Council, Wetlands Team. www.itrcweb.org.

O’Niell, W. L., and V.A. Nzengung. 2000. “Treatment of Organic-Contaminated Water in Microbial Mat Bioreactors,” Symposium Series: Case Studies in the Remediation of Chlorinated and Recalcitrant Compounds, G. B. Wickramanayake, A. R. Gavaskar, J. T. Gibbs, and J. L. Means, eds. Columbus, Oh.: Battelle Press, 2(4): 347–52.

O’Niell, W. L., V. A Nzengung, and A. Adesida. 2000. “Treatment of Perchlorate-Contaminated Water in Microbial Mat, Algae, and Ebb-and-Flow Hydroponics Bioreactors,” Symposium Series: Case Studies in the Remediation of Chlorinated and Recalcitrant Compounds, G. B. Wickramanayake, A. R. Gavaskar, J. T. Gibbs, and J. L. Means, eds. Columbus, Oh.: Battelle Press 2(7): 101–06.