Case Study as part of a Web-based

Technical and Regulatory Guidance

Lava Cap Mine

Nevada County, California

1. Site Information

1.1 Contacts

Steven Ross

Hazardous Substance Engineer

California Department of Toxic Substances Control

Sacramento Field Office

8800 Cal Center Drive

Sacramento, CA 95826-3200

Telephone: 916-255-3694

E-mail: [email protected]

Rusty-Harris Bishop

EPA Site Manager

75 Hawthorne Street (SFD-7-2)

San Francisco, CA 94105

Telephone: 415-972-3140

E-mail: [email protected]

McKinley Lewis, Jr.

California Department of Toxic Substances Control

Telephone: 916-255-3625

E-mail: [email protected]

Figure 1-1. Site location map.

1.2 Name, Location, and Description

The Lava Cap Mine site occupies approximately 33 acres in a semirural, residential

area of the Sierra Nevada foothills in western Nevada County, California

(Figure 1-1). The site is approximately 5 miles southeast of Nevada City

and 6 miles east of Grass Valley at an elevation of about 2700 feet. The

site includes the mining area where ore was processed to recover gold and

areas where tailings which originated at the mine have been washed downstream

and deposited over time. The downstream areas of the site include Lost

Lake, a private lake surrounded by homes, located approximately 1.25 miles

downstream of the Lava Cap mine site. In 1994, an estimated 1,776 people

lived within 1 mile of the site, and 24,091 lived within 4 miles of the

site. The EPA formally listed the Lava Cap Mine site on the National Priorities

List (NPL) in February 1999, allowing Superfund funding to be spent on

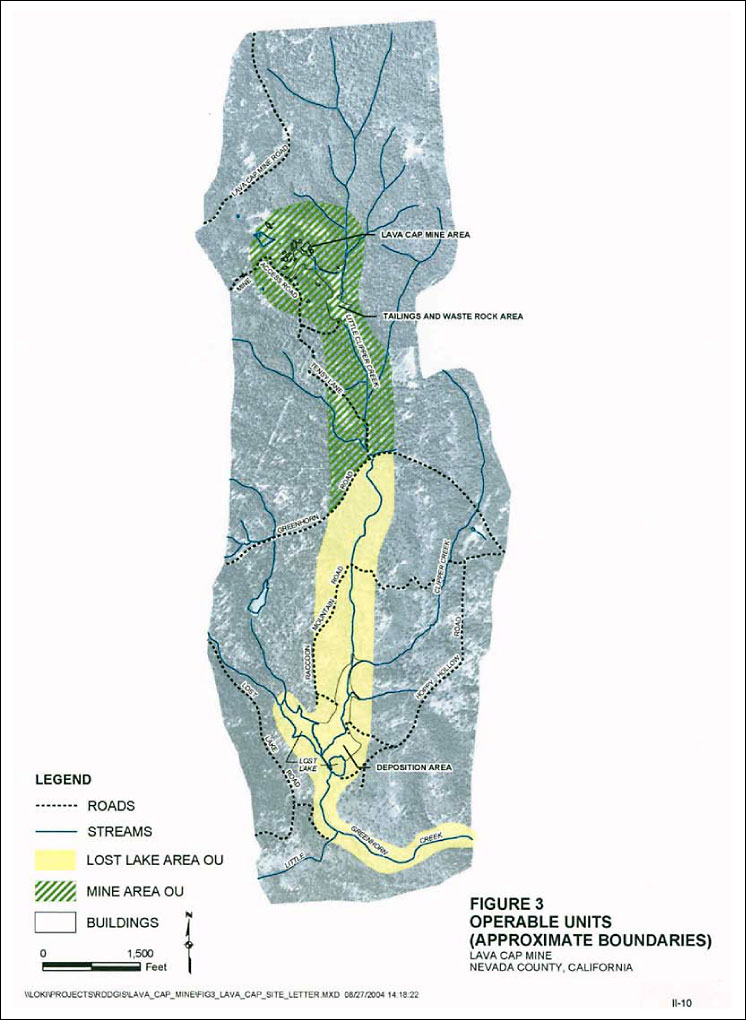

investigation and cleanup of the site. In 2004, as a result of initial

studies of the site, EPA divided site into four project areas, or Operable

Units (Figure 1-2).

Figure 1-2. Operable units.

Gold and silver mining activities were initiated at Lava Cap Mine in 1861. From 1861 to 1918, processing of the ore and disposal of the waste rock, overburden, and tailings occurred off site at the Banner Mine, which is located approximately 1.5 miles north of the Lava Cap Mine.

The Lava Cap Mine was inactive from 1918 to 1934, at which time mining activities were resumed and a flotation plant was built to process the ore at the site. The gold and silver concentrates from the flotation plant were shipped to two smelters, one in California and the other in Washington. In 1940, a cyanide plant was built to recover the concentrates on site. However, this operation proved to be relatively ineffective. From 1941 to 1943, the cyanide plant handled only the middlings and tailings from the flotation plant. The middlings and tailings were ground very fine, then vat-leached with cyanide to remove the residual gold and silver. Slurries from the flotation and cyanide processes were deposited in a ravine on the site. Where the ravine steepened and narrowed, a log dam approximately 60 feet high was built to hold the tailings in place. The waste rock and overburden were also deposited in two piles located at the site between the mineshaft and the tailings pond. In 1943, Lava Cap Mine was closed due to World War II. An attempt was made to reopen the mine in the mid-1980s. However, community opposition resulted in the defeat of a proposed rezoning of the property which would have allowed mining activities to resume at the site.

The primary contaminant from the Lava Cap mine is arsenic in the mine tailings, both on the mine property and in the Little Clipper Creek watershed from the mine down to Lost Lake. Arsenic is also found at elevated levels in the water of the creek and the lake and in shallow groundwater below the tailings.

In 1979, complaints from local residents initiated an action from California’s Central Valley Regional Water Quality Control Board (RWQCB) that led to issuance of a Cleanup and Abatement Order (CAO). The CAO called for the property owners at that time to take measures to limit tailings discharges to Little Clipper Creek, to divert surface water runoff from the mine and mill waste fill deposits, and to obtain an evaluation of the dam. This order resulted in the construction of three small settling basins below the dam and some flow diversions around the tailings. No improvements were made to the dam.

During a major winter storm in January 1997, the upper half of the log dam collapsed, releasing over 10,000 cubic yards of tailings into Little Clipper Creek. In early 1997 staff from the California Department of Fish and Game and the Nevada County Department of Environmental Health inspected the site. Extensive deposits of tailings were observed in and on the shoreline of Little Clipper Creek, at the confluence of Little Clipper and Clipper Creeks, and in and on the shoreline of Lost Lake. The tailings were also observed in wetland areas contiguous with these water bodies, in some cases completely covering the vegetation.

Several times during 1997, the California Department of Toxic Substances Control has conducted sampling at the mine site and off site at Lava Cap Mine to determine the locations and concentrations of arsenic contamination. Following the dam collapse in January 1997, the current property owner constructed a drainage ditch upstream of the mill tailings, which partially diverted surface away around the tailings.

Samples of drinking water wells near the mine site have shown elevated levels of mine-related arsenic, in concentrations varying from 2 to 90 times the drinking water standard of 10 parts per billion. Each of these residences has a treatment unit for its drinking water supply; therefore, EPA believes no one is currently ingesting arsenic-contaminated drinking water above the drinking water standard.

2. Remedial

Action and Technologies

The main goals for this site are to protect human health and the environment

from exposure to arsenic in soil and sediments and implement treatment

of contaminated surface water emanating from the mine and from the tailings

disposal area which flows into the local drainage.

In October and November 1997, 4,000 cubic yards of tailings was removed from the damaged dam area and stockpiled on the waste rock pile immediately to the north of the tailings pile. The lower half of the dam (i.e., approximately 30 feet in height) was found to be in relatively good condition. The over-steepened slopes of the tailings pile immediately behind the dam were graded, and the entire tailings pile was covered with waste rock. Stream diversions were also created around the tailings pile. In February 1998 a second response was constructed at the site to stabilize another tailings release and to further improve the drainage. The removal action has been completed and included covering approximately 4,000 cubic yards of stockpiled tailings with a clay cap.

In 2005, the Remedial Action for the Mine Area Residences Operable Unit was conducted. The primary focus of the remedy was to excavate any contaminated soil present around the Mine Area residences, backfill the excavated areas with soil transported from a clean borrow source, and consolidate excavated material in the tailings disposal area for long-term management. Associated activities included storm-water control and paving roads/driveways that had been covered with mine waste materials.

Excavated tailings and contaminated soils from Little Clipper Creek as well as surrounding the residences have been consolidated under the multilayered cap. Surface water is routed around the cap and over the rock-wall buttress, preventing water from infiltrating the mine tailings. Revegetation along Little Clipper Creek occurred in November 2007. Surface water treatment is expected to begin by late spring 2010 after additional treatability studies. Water that is discharging from the mine will be treated to ensure water quality downstream. The primary mechanism is for this stage is coprecipitation of As with ferric iron solids.

Several treatability studies have been conducted, including chemical precipitation (FeCl3 coprecipitation), jar tests, isotherm testing, zero-valent iron (ZVI) column testing, ZVI on-site pilot testing, semipassive treatment lab testing, and constructed microbial mats (Bender et al. 1994).3. Performance

The primary performance standard for the Mine Area Residences OU Remedial

Action was to remove contaminated materials that exceed USEPA’s cleanup

standard of 20 mg/kg, except in roadways where contaminated materials were

capped with asphalt. Confirmation of performance for the roads was based

on visual assessment of the paving activities to ensure that the entire

road was covered. To ensure that all contaminated materials were removed

from the excavations, confirmation samples were collected from the floor

and walls of the excavation in each separate excavation area. Preconstruction

sample results of the contaminated materials generally ranged 100–2,200

mg/kg. With the completion of the mine area cap, this action will prevent

the further release of mine tailings to the Little Clipper Creek watershed

down to Lost Lake.

4.

Costs

Capital: $8 million for caps, diversion channels, buttress, and other

construction work.

Operation and maintenance: None to date.

5. Regulatory Challenges

None reported.

6. Stakeholder Challenges

Recreational access to the Lost Lake area 1.5 miles downgradient of the

mine area where the arsenic-laden sediments have deposited by the drainage

system exposes residents to contamination. To minimize this risk, EPA recommended

that people limit their contact with the mine tailings and that those who

walk along the tailings deposition areas of Little Clipper Creek and Lost

Lake rinse their shoes afterward. EPA further recommended that people limit

the ingestion of water from Little Clipper Creek and Lost Lake.

7.

Other Challenges and Lessons Learned

The project capital costs for the remedial action at the Mine Area Residences

Operable Unit were somewhat higher than the estimate, and a portion of that

was attributed to overly optimistic estimates of the amount of time that

would be required to complete the construction and underestimating the difficulties

in working around a difficult tenant residing in the construction area. Schedule

estimates and oversight cost estimates need to account for potential unforeseen

difficulties that may be encountered in the field, particularly on a relatively

small construction project where the oversight costs are a larger portion

of the project total.

Effort should be expended prior to construction to ensure that a source of clean backfill is available locally that meets the project requirements. Although a number of sources of fill were identified, they all contained arsenic at concentrations in excess of the cleanup goal of 20 mg/kg because much of the local soil in the region comes from the weathered bedrock of this mineralized area.

Residents are concerned about vehicles on private roads and in the neighborhood. There are also low water yields reported in some residential wells just south of the mine area. Treatment process is ongoing in an attempt to find a low-cost, low-maintenance option for treating contaminated water.

8. References

Bender, J., J. P. Gould, Y. Vatcharapijarn, J. S. Young, and P. Phillips.

1994. “Removal of Zinc and Manganese from Contaminated Water with Cyanobacteria

Mats,” Water Environment Research 66(5): 679–83.

California Department of Toxic Substances Control. n.d. “Lava Cap Mine Envirostor Website.” www.envirostor.dtsc.ca.gov/public/profile_report.asp?global_id=29100004.

U.S.

Environmental Protection Agency Region 9. n.d. “Lava Cap Mine.” http://yosemite.epa.gov/r9/sfund/r9sfdocw.nsf/ce6c60ee7382a473882571af007af70d/7f29f3b3740158ca88257007005e944f.