Case Study as part of a Web-based

Technical and Regulatory Guidance

Fire Road Mine

Sunbury, New Brunswick

1. Site Information

1.1 Contacts

Michele Coleman

Telephone: 506-327-2228

E-mail: [email protected]

1.2 Name, Location, and Description

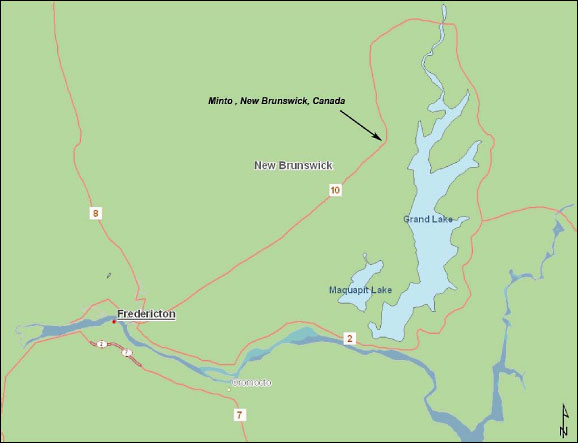

The Fire Road Mine is located in Minto, Sunbury, New Brunswick (Figure

1-1), 13 km off a major road. A surface coal mine covering 100 hectares (ha)

was operated 1982–1985. The coal was located under 10–20 m of overburden and

is located in an area of predominantly sandstone and conglomerate with visible

pyrite nodules. The mine was reclaimed using less porous materials than the

surrounding host rock. Therefore, groundwater and surface water flow preferentially

through the waste rock. The acid mine drainage (AMD) is characterized by a

pH of 3.5 and high concentrations of iron (10 ppm) and aluminum (60 ppm). The

flow varies from less than 300 gallons per minute (gpm) to approximately 2400

gpm during spring runoff.

Figure 1-1. Map of Fire Road Mine, Minto, New Brunswick. Source: ArcGIS Desktop Version 9.3.1.

2. Remedial Action and Technologies

A hydrated lime water treatment plant was constructed in 1986 to treat the

AMD using chemical precipitation. The discharge is being treated pursuant

to the Clean Water Act and to mitigate the ecological risk. Primary contaminants

include acidity, aluminum, and iron. The performance of the treatment process

is evaluated by monitoring the treatment pH. Additional testing of fish lethality

of the effluent is performed three times per year. Beginning in 1992, the

sludge generated from the chemical precipitation process has been recycled

to the waste rock to reduce the consumption of lime by approximately half.

Each time the sludge is recycled to the waste rock, an increase in pH and

decrease in aluminum and iron concentrations are observed.

3. Performance

Coal mine water has 3.5 pH. Hydrated lime is used to neutralize the acidity.

Aluminium and iron contaminants are then precipitated.

4. Costs

Capital costs for the chemical precipitation process were reported at $50,000

per year. Ongoing operation and maintenance costs are approximately $300,000

per year.

5.

Regulatory Challenges

None encountered.

6. Stakeholder Challenges

No information available.

7. Other Challenges and Lessons

Learned

As noted above, the sludge is recycled into the waste rock. The increase

in pH and drop in aluminum and iron concentrations follow and spike after

each dredging cycle. Lime consumption has been reduced by over half since

this started in 1992.

8. References

No information available.