Case Study as part of a Web-based

Technical and Regulatory Guidance

Keystone & Rising Star Mines

Shasta County, California

1. Site Information

1.1 Contacts

Central Valley Regional Water Control Quality Board

Contact: Philip Woodward

Telephone: 530-224-4853

E-mail: [email protected]

Vestra Resources, Inc.

Contact: John Andrews

Telephone: 530-223-2585

E-mail: [email protected]

1.2 Name,

Location, and Description

This case study presents the results of the implementation of constructed

treatment wetlands technology in Keystone and Rising Star mines. Keystone

Mine is in section 14, T33N, R6W, MDB&M (CRWQCB CVR 2002), located approximately

4.5 miles west of Shasta Dam and 9 miles northwest of Shasta Lake City (latitude

40.72187N, longitude 122.50388W), in Shasta County, California. Rising Star

and Bully Hill mines are in sections 15, 16, 21, T34N, R3W, MDB&M (CRWQCB

CVR 2003), located approximately 10 miles northeast of Shasta Dam and 19

miles southwest of Shasta Lake city (latitude 40.79410N, longitude 122.20938W),

in Shasta County, California. (Figure 1-1.) Both mines are located on private

land.

Figure 1-1. Location map for Keystone and Rising Star mines.

Created with ArcGIS Desktop Version 9.3.1.

Balaklala, Keystone, and Shasta King mines were owned by Silver King Mines Inc., of Lake City, Utah. It pertains to the Lake Shasta Drainage Hydrologic Area (No. 506.20) as depicted on interagency hydrologic maps prepared by the Department of Water Resources (DWR) in August 1986. Keystone Mine was explored in 1900 and again in 1918. The mine produced mainly copper from 1923 to 1925 and includes two adits and 2,000 ft of drifts and crosscuts (Smith 1995) in an area of 15 acres. The principal towns around the site are Shasta, Shasta Lake, and Redding.

The extraction of large quantities of ore from the mines resulted in extensive development of the underground workings, being the principal source of contamination, acid mine drainage (AMD). Broadly, AMD is formed when rainwater infiltrates into the mine workings through soil and rock. This water contacts sulfide deposits open to air in the old tunnel complexes of the mines. The ensuing chemical reaction among significantly lowers the pH of the water. As this water moves out of the mine tunnels, its acidic nature leaches metals from the rocks. The discharge, commonly from mine portal, is toxic to fish and other aquatic organisms but is not hazardous to human health. Particularly, Keystone Mine discharges 2 miles upstream of confluence with Lake Shasta with copper, cadmium, and zinc in solution as toxic contaminants.

From 1980 to 2000 the mine owners implemented numerous remedial measures at the mines, including the installation of concrete bulkhead seals in the mine portals. However, the seals are only partially effective because AMD is discharging from adits, seeps, and fractures around the Keystone Mine, in violation of discharge prohibitions, discharge specifications, and receiving water limitations contained in the existing National Pollution Discharge Elimination System (NPDES) permit.

Rising Star MineRising Star Mine is approximately 100 acres and is one of two neighboring inactive copper mines in the East Shasta Copper Mining District in central Shasta County near Shasta Lake. The area is at edge of the Klamath Mountains (geomorphic province). The access to the site is limited to boat or two-hour drive over narrow dirt roads. The Rising Star and Bully Hill Mines were initially worked for gold and silver in the early 1860s. In the late 1800s through 1927, copper and zinc were also mined. Although exploratory work was performed in the area in the 1950s, there has been no production since 1927. Placer gold, silver, and copper were extracted from both mines. Bully Hill is the closest abandoned mine to the current shoreline Shasta Lake. A large ore smelter was once located at Bully Hill. Portions of the tailings and a debris dam at Bully Hill are inundated when the reservoir is full. Additional remedial actions have been proposed to control runoff from these mines, including removing or capping extensive tailings. AMD from these mines affects Town and Horse creeks and localized water quality in Shasta Lake (Ecosystem Restoration Opportunities Office 2003).

The extraction of ore from the mines resulted in extensive development of underground workings, creation of large waste rock dumps, and tailings piles at the nearby Bully Hill Smelter. The mine workings and waste rock dumps are the principal sources of low pH and metal-laden discharges referred to as acid rock drainage (ARD) (CRWQCB CVR 1997). ARD historically discharged from the lower portals of the Rising Star Mine which have been plugged; however, ARD continues to seep from the bedrock and enter surface waters. The two main mine portals of the Rising Star Mine were sealed by the discharger in 2004, appreciably reducing ARD discharges to surface waters.

2. Remedial Action and Technologies

The primary impacts on aquatic life are caused by the heavy metals copper,

cadmium, and zinc. Specifically, Keystone Mine AMD flow stream from the concrete

bulkhead seal flowed at 5–10 gpm joined the discharge from the Balaklala

and Windy Camp mines (EPA 1994). Table 2-1 shows the typical metal concentrations

and ranges of discharge.

Table 2-1. Typical metal concentrations of Keystone Mine discharge

Constituent |

Concentration |

5 gpm discharge [kg/year] |

10 gpm discharge [kg/year] |

| pH | 2.9–3.8 |

NA |

NA |

| Cooper | 2–13 mg/L |

20–130 |

40–260 |

| Cadmium | 3–21 mg/L |

30–210 |

60–420 |

| Zinc | 0.02–0.12 mg/L |

0.2–1.2 |

0.4–2.4 |

| Iron | 9–140 mg/L |

90–1,400 |

180–2,400 |

| Source: Concentrations from EPA 1994. Elaboration by ITRC: Discharges calculated using 5 and 10 gpm AMD flows—2 mg/L × 5 gal/min × 3.785 L/gal × 60 min/h × 24 h/d × 365 d/y × 1 kg/10∧6 mg = 20 kg/y. |

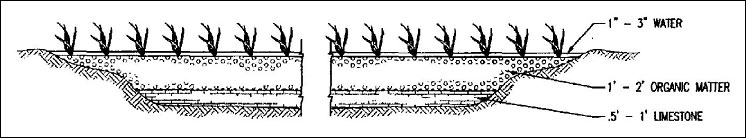

The treatment technology in place at the site is constructed treatment wetlands

(CTW). Basically, it consists in a vertical flow of water to be treated using

anaerobic conditions at the base to precipitate heavy metals out as sulfides.

Figure 2-1 shows a scheme of this technology. Approximately 5–10 gpm have

been treated for eight years using CTW and will continue indefinitely.

Figure 2-1. Scheme of an anaerobic system of constructed treatment wetlands.

Source: Baum and Mercurio 1997.

3. Performance

The goal is 99% removal of metals from the waste stream. However, the CTW

is very unlikely to meet this goal because it was demonstrated that this

passive treatment system has a performance of 90% removal. Using data from

Table 2-1, the amount of heavy metals removed using CTW technology was calculated

as shown in Table 3-1.

Table 3-1. Removal effects after using CTW technology in Keystone Mine AM

Constituent |

Concentration |

Quantity removed in a 5 gpm discharge (kg/year) |

Quantity removed in a 10 gpm discharge (kg/year) |

| Cooper | 0.2–1.3 |

18–117 |

36–234 |

| Cadmium | 0.3–2.1 |

27–189 |

54–378 |

| Zinc | 0.002–0.012 |

0.18–1.1 |

0.36–2.2 |

| Iron | 0.9–14 |

81–1,260 |

62–2,160 |

ITRC (2003) reported the performance of the Rising Star Mine constructed

treatment wetlands. The initial concentration in the range 0.072–0.47 mg/L

and was reduced by the treatment to 0.009–0.303 mg/L.

4. Costs

Capital:

$2,000,000 (for activities at Keystone Mine).

Operation and maintenance (O&M): $10,000 per year indefinitely. A similar cost is assumed for both Keystone and Rising Star mines. Specific O&M cost may vary from $0.77/yd3 to $0.38/yd3 for a corresponding volume of 13,000 yd3/year to 26,000 yd3/year.

5.

Regulatory Challenges

The application of CTW does not face any regulatory barrier under California

state laws. However, the Regional Water Quality Control Board (RQCB) encourages

innovative technologies to deal with AMD and/or ARD in remote regions with

no access to infrastructure, for instance, electricity and other activities.

In this case, the wetlands treatment system cannot consistently meet numeric effluent limits designed to protect all beneficial uses, including protection of aquatic life and sensitive fish species. The RQCB is currently attempting to develop a policy to allow for implementation of best management practices in lieu of numeric effluent limits as allowed in 40 CFR 122.44(k)(3).

6. Stakeholder Challenges

There is some concern that the residual metals in the watershed are impacting

fish downstream in Shasta Lake and beyond in the Sacramento River. The RQCB

believes all feasible remedial activities have been completed and downstream

impacts from heavy metals are minimal. Some members of the public will object

to the best management practices approach and will claim that all discharges

can be treated to meet the lowest criteria for protection of beneficial uses.

In relation with Best Management Practices, some members of the public will object this approach and will claim that all discharges can be treated to meet the lowest criteria for protection of beneficial uses.

7.

Other Challenges and Lessons Learned

Reducing metal concentrations discharged to watercourses by 90% is an excellent

result using only passive treatment systems; however, this is still not adequate

according to state and federal laws. The agencies are reluctant to recognize

that not all watersheds can be brought up to “fishable and swimmable standards.”

Over the next five years, RQCB will be dealing with convincing other agencies

that assigning beneficial uses to a specific watercourse may not be appropriate.

Also, it will be take care about the recognition that not all watercourses

will support fish. Regarding CTW implemented near Rising Star Mine, protection

against vandals is very important because the public can gain easy access

to the site.

8. References

NOTE: No references were mentioned in the survey, but those below were used

to complete of this case study.

Baum, M., and L. Mercurio. 1997. “Proposal for Funding for Remediation of Inactive Mines Located in the West Squaw Creek Watershed.” Mining Remedial Recovery Company.

CRWQCB CVR (California Regional Water Quality Control Board, Central Valley Region). 1997. “Order No. 97-215,” requiring Millennium Holdings, Inc., Bully Hill and Rising Star Mines, Shasta County to cease and desist from violating waste discharge requirements.

CRWQCB CVR. 2002. “Waste Discharge Requirements for Mining, Remedial Recovery Company, Inc.” Mammoth, Sutro, Keystone, Stowell, Balaklala, Shasta King, and Early Bird mines, Shasta County.

CRWQCB CVR. 2003. “Monitoring and Reporting Program Order No. R5-2003-0039.” Millenium Holdings Inc., Bully Hill and Rising Star Mines, Shasta County.

Ecosystem Restoration Opportunities Office. 2003. Shasta Lake Water Resources Investigation. p. II-6.

EPA (U.S. Environmental Protection Agency). 1994. Technical Resource Document: Extraction and Beneficiation of Ores and Minerals. p. 1-36.

ITRC (Interstate Technology & Regulatory Council). 2003. Technical and Regulatory Guidance for Constructed Treatment Wetlands. WTLND-1. Washington, D.C.: Interstate Technology & Regulatory Council, Mining Waste Team. www.itrcweb.org. p. 38.

Smith, D. 1995. Historic Data Inventory of the Shasta County Interlakes Special Recreation Management Area. Bureau of Land Management. pp. 22–24, 59, 138.