Case Study as part of a Web-based

Technical and Regulatory Guidance

Hartshorne/Whitlock-Jones

Pittsburg County, Oklahoma

1. Site Information

1.1 Contacts

Dr. Robert W. Nairn

The University of Oklahoma

School of Civil Engineering and Environmental Science

202 West Boyd Street, Room 334

Norman, OK 73019

Telephone: 405-325-3354

E-mail: [email protected]

1.2 Name, Location, and Description

“The former Rock Island Coal Mining Co. Mine 7 is located immediately

east of Hartshorne, OK and was one of a series of mines operated by the Rock

Island Coal Mining Co. during the early part of the 20th century. The No.

7 mine was abandoned in the 1930’s and utilized three shaft entries and two

parallel slope entries access the abandoned underground workings. An artesian

acid mine drainage (AMD) discharge, ranging from the 19 to 76 L/min (5 to

20 GPM) of highly mineral-laden water discharges from a 55-m (180-ft) deep

airshaft” (Behum, Meier, and Bohnenstiehl 2004). See Figure 1-1.

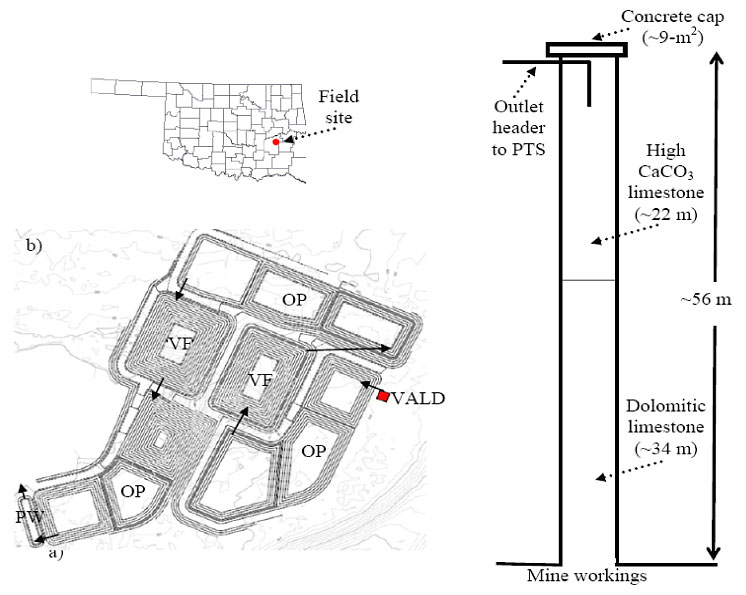

Figure 1-1. Hartshorne/Whitlock-Jones, Hartshorne, Pittsburg County, Oklahoma.

(N 34°, 50.7' [34.8450], W 95°, 33.4' [-95.5562]. Source: Google Earth 2009)

2. Remedial Action and Technologies

“Prior to construction, the mine discharge was sampled periodically

for several years and showed considerable fluctuation in both water quality

and quantity. Measured discharge rates ranged from <1 to approximately

75 LPM. Metal and anion concentrations varied with each sampling event,

although temperature, pH, and DO remained relatively consistent. The acidic

nature of the discharge, coupled with median concentrations of iron (Fe)

and Mn (Manganese) of 765 and 18mg/L, respectively, warranted a plan for

treatment.

3. Performance

“Due to the design of the VALD [Figure 3-1], sampling of the original

mine discharge is currently impossible. The VALD effluent is considered

the best approximation of the discharge water quality. Water quality and

quantity data collected from the VALD effluent from January 2007 through

June 2008 demonstrate that this mine discharge remains highly mineralized,

containing elevated metals, base cations, SO42-, and Cl-. Metal and anion

concentrations and discharge rates were highly variable, remaining consistent

with pre-construction data. However, temperature, pH, and DO remained relatively

consistent over the sampling period. The maximum concentrations for all

metals, all anions, alkalinity, and conductivity occurred in the first

sampling event after the VALD first began to flow. Concentrations of metals

and anions decreased for sampling events since then, with the majority

of the minimum concentrations occurring in the last sampling event during

the study.

“The purpose of the VALD is to generate alkalinity to sustain Fe oxidation in subsequent unit processes. In this regard, the VALD is performing effectively.… [A] typical anoxic limestone drain can be expected to add up to 150–300 mg/L as CaCO3 of alkalinity. Alkalinity concentrations in the VALD effluent averaged 470 ± 49 mg/L (mean ± standard deviation) as CaCO3 during the period of study. The cause of these unusually high alkalinity concentrations is likely due to several factors, including the ionic strength of the mine water, elevated pCO2 (~10-0.3 entering the VALD), and retention time (25 to 53 hours) of the water in the VALD…. As a result of alkalinity generation as well as decreases in metals concentrations, the net acidity of the discharge decreased from a pre-construction value of 1288 mg/L as CaCO3 to 614 ± 498 mg/L as CaCO3.

Figure 3-1. Rock Island #7 field site showing location in Oklahoma; schematic of passive treatment system with location of VALD (base drawing courtesy Burns and McDonnell 2004) showing general direction of flow (OP = oxidation pond, VF = vertical flow cell, PW = polishing wetland); and generalized diagram of VALD. (After Behum, Meier, Bohnenstiehl 2004. Note: Not to scale.)

“Although the Rock Island #7 passive treatment system was designed primarily for the removal of Fe from the mine discharge, it has been very effective at removing other metals as well. The system, on average, has exhibited Fe removal and alkalinity generation rates that compare well to those found in the literature. However, these rates fluctuate widely due to the highly variable water quality and quantity entering the system. In order to understand the system more fully, more information must be gathered on the retention time of the water in the system and the unit processes themselves. This will aid greatly in resolving the issue of location-event sample matching. Also, a thorough evaluation of the biotic processes occurring in both the oxidation ponds and vertical flow cells is necessary to gain a better understanding of how the system treats this unique mine discharge. Gathering a wider array of data on this system will help in further determining the efficacy of treatment. Despite these gaps in data, it is evident that the treatment system is discharging water with much higher quality that the original mine discharge” (Labar and Nairn 2009).

4. Costs

No information was included with this survey.

5. Regulatory Challenges

No regulatory issues were encountered.

6. Stakeholder Challenges

There were no significant public or stakeholder issues associated

with the project.

7. Other Challenges and Lessons Learned

Learning to work with private landowners was critical, and there

was a need to demonstrate how remedial technologies would benefit

them.

8. References

Behum, P. T., L. Meier, and K. Bohnenstiehl. 2004. “Application

of LIDAR Imagery in AML Reclamation: Case Example—Design of an AMD

Passive Treatment System at the Rock Island No. 7 Airshaft, Oklahoma,”

in Proceedings, Advanced Integration of Geospatial Technologies

in Mining and Reclamation, Atlanta, December 7–9.

Labar, J. A., and R. W. Nairn. 2009. “Evaluation of First 1.5 Years of Operation of a Passive Treatment System in SE Oklahoma,” pp. 693–708 in Proceedings, Joint Conference of American Society of Mining and Reclamation 26th Annual Conference and 11th Billings Land Reclamation Symposium, Billings, Montana.

Labar, J. A., R. W. Nairn, and G. A. Canty. 2008. “Generation of 400–500 mg/L Alkalinity in a Vertical Anoxic Limestone Drain,” in New Opportunities to Apply Our Science, Proceedings, 25th National Meeting of the American Society of Mining and Reclamation, Richmond, Virginia, June 14–19.