B.15 Luttrell Site Case Study

B.15.1 Contacts

The remedial project manager for the Upper Tenmile Creek Superfund Site is Tillman McAdams, and for the Basin side of the site, Kristine Edwards. The site contractor is CDM Smith, and the project manager is David Shanight.

B.15.2 Name, Location, and Site Description

The Luttrell site receives waste rock from the Upper Tenmile Creek Superfund Site and the BCR treats the effluent from that waste rock repository. The Upper Tenmile Creek Mining Area site is located in the Rimini Mining District, southwest of Helena, Montana. This site consists of numerous abandoned and inactive hard-rock mine sites that produced gold, lead, zinc, and copper. Mining began in the district before 1870 and continued through the 1920s. Little mining has been performed there since the early 1930s. USEPA added the Upper Tenmile Creek Mining Area to the Superfund National Priorities List on October 22, 1999, due to mining waste problems in the 53 square-mile watershed.

The small historic mining community of Rimini is located within the Superfund site boundaries. The site includes the drainage basin of Tenmile Creek upstream of the Helena water treatment plant and includes tributaries that supply water to the plant's five intake pipelines. USEPA identified 150 individual mine sites within the watershed boundary, of which 70 have been prioritized for cleanup. Many of these mines are above the five drinking water intakes for the City of Helena, which supply about 50% of the city's water.

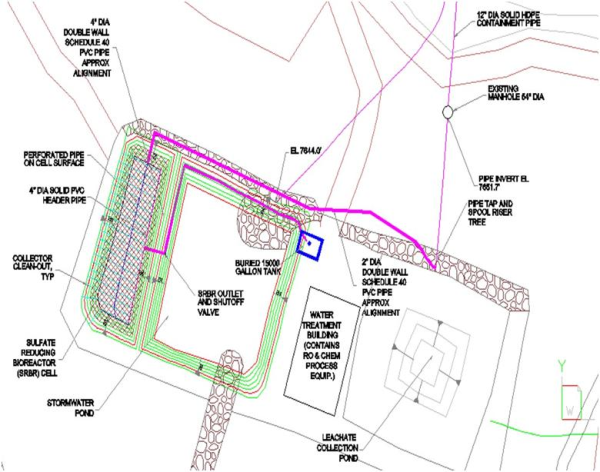

B.15.3 BCR Design

A schematic of the BCR is presented in Figure B.15-1. The cellAn individual unit in a treatment system. has a bottom surface area of approximately 3,600 square feet. The substrateEither (a) a chemical which reacts or (b) a solid surface or (c) an electron donor. used in the BCR includes a mixture of manure, wood chips, and straw, along with coarse limestone gravel for support. The BCR was filled, and the bacteria were given a long adaptation period from October 2002 to June 2003. During this period, the initial filling was supplemented only by rain and snowmelt, and the BCR lost some water by evaporation.

Some of the repository leachate has been diverted from the effluent pipe of the repository and has created input flows from 1 to 2.5 gpm to the BCR over the life of the reactor. The BCR influent pipe enters at the top of the BCR and the water flows vertically downwards through the cell. Water at the bottom of the cell is collected in a series of perforated collector pipes that lead to the main drain pipe that discharges on the east side of the cell (into the storm water cell). During the summer treatment season, a line is also connected to the BCR effluent pipe, which allows water transfer to a 15,000 gallon underground storage tank. This line also allows water to be pumped into a truck or into the leachate pond, depending on varying volumes of snowmelt, stormwater, and leachate to manage each season. The BCR effluent is eventually routed with other collected waters to be treated in the active water treatment plant and is not directly discharged.

Figure B.15-1. Schematic of the Luttrell BCR.

The BCR has no flow in or out during the winter months (generally October through May) because snowfall and the lack of permanent buried plumbing restrict site access. In the winter, repository leachate drains to a leachate collection pond, where it is held for treatment the next season. Clean snowmelt that accumulates on top of the BCR is pumped into the adjacent stormwater pond.

B.15.4 BCR Operation and Data Collection

The BCR was filled and the bacteria were given a long adaptation period from October 2002 to June 2003. During this period, the initial filling was supplemented only by rain and snowmelt, and the BCR lost some water by evaporation. In 2005 and 2006, a more thorough study of the BCR effluent was undertaken to assist Region 8 in understanding how to use the BCR effluent for different mixing, while demonstrating the longevity of passive treatment for the repository leachate. This testing included various options of mixing either (1) with the treatment plant discharge and sending to the land application devices for discharge, or (2) mixing with the leachate to raise the pH of the leachate and reduce the chemical costs of treating the leachate in the chemical precipitation plant.

In 2006, a black liner was placed on the top of the BCR for two main purposes. First, the liner was installed to prevent significant snowmelt from entering the BCR every spring from the nearby the road and hillside. A small surface drain was placed at the opposite corner of where the snowmelt and water enter the BCR. Since the objective of the BCR project was to study passive treatment, it was hoped that the water would drain from the top of the reactor into the stormwater pond adjacent to the BCR. Second, the cover was installed in conjunction with an USEPA ORD project to measure the temperature at different levels inside the BCR that started in 2005. Because the BCR is at roughly a 7800 foot elevation, the USEPA ORD project manager believed that the black liner would be heated by sunlight and the temperature of the BCR would increase more rapidly. Heavy sandbags secured the liner.

Shortly after placing the liner on the BCR, several events occurred. The liner raised the temperature of the upper levels of the BCR, but some of this increase was also attributed to the exothermic reaction created by the microbes in the BCR. At first, this latter input was probably minimal, but later the gases began lifting the liner in many areas. This process continued throughout the treatment season and has occurred every year. The drain was effective at removing the water, but it appeared to remove too much water and the hydraulic headA specific measurement of water pressure above a geodetic datum. It is usually measured as a water surface elevation expressed in units of length. on the BCR changed and affected flow from the effluent line. The drain was plugged and the flow issue has not occurred again.

In 2007, Region 8, ORD, and CDM discussed the future of the system. The original design of the passive treatment system at Luttrell used two BCRs treating approximately 3-5 gpm each. Since the modeled flow from the final capped repository was estimated to be 6-9 gpm, changes would have to be made to the repository leachate piping, and the new BCRs would have to be located to allow for gravity draining. The existing pilot system does not have an adequate grade to drain into the leachate pond for pumping to the land application disposal site if the BCR is used without the precipitation plant. The metal loadingMass of something per time entering a volume (volumetric loading rate) or flowing into an area (areal loading rate). to the land application disposal site would also have to be re-calculated. The 2005-2006 experiments showed that mixing the BCR effluent with the leachate pond raised the leachate pH by 2 – 2.5 units, and it was decided to continue that approach. The BCR has been used for pre-treatment during 2007-2012, and CDM Smith has collected data during this time.

The BCR is the oldest constructed reactor at this elevation in the United States. The BCR is now 10 years old, and the last analyses completed by ORD in the fall of 2010 (Butler 2010) showed significant metals removal (aluminum, arsenic, cadmium, copper, and zinc are greater than 98%). In that same ORD peer-reviewed publication (Butler 2010), Luttrell had greater metal removal efficiency (MRE) for most metals, than the newer BCRs at Park City, UT and Crested Butte, CO.

B.15.5 MIW Water Chemistry and BCR Effluent Chemistry

The Luttrell BCR was built in September 2002 and the BCR was filled with repository leachate water over a period of weeks, so the influent water includes a range of values (see Table B.15-1). A substantial number of water chemistry analyses have been completed over the last 10 years, and it is difficult to summarize these in one short document. The influent water chemistry varies due to several factors and is highly depends on the amount of precipitation that enters the repository during the treatment season. During that time, a temporary cover may not have been over part of the repository, so the metals content of the leachate water would depend on percolation through the uncovered material in the repository. The uncovered material may have come from yard removal material (high in arsenic) or from material piles near abandoned mine sites in the superfund site boundaries.

The effluent from the BCR also varies with the time of year that it is collected. For example, the first effluent released when the BCR is started in the spring is black, with high biological oxygen demand (BOD), low dissolved oxygen (DO), low metals, and the lowest sulfate numbers for the year. This water has had a residence time in the BCR of at least 6 months, whereas effluent samples taken in September or October may have much shorter residence times (from a few days to a week or so). Table B.15-1 presents example data over eight years of the 10-year period. An upcoming publication will detail the water chemistry.

|

Analyte Name |

Initial Water Input to Cell 9/2002* |

Initial Effluent Totals 04/29/03 |

Effluent 09/26/03 |

Effluent 8/18/04 |

Influent 7/2/2008 |

Effluent7/2/2008 |

Influent 9/30/2010 |

Effluent 9/30/2010 |

|---|---|---|---|---|---|---|---|---|

|

Aluminum |

8 to 22 |

0.002 |

0.32 |

0.51 |

18.22 |

0.02 |

28 |

BDL |

|

Arsenic |

0.25 |

0.251 |

NM |

NM |

0.29 |

0.06 |

2.5 |

0.04 |

|

Calcium |

340 to 354 |

45 |

1439.77 |

692.68 |

302 |

612 |

NR |

NR |

|

Cadmium |

3.1 to 3.3 |

0.034 |

0.01 |

0.01 |

0.91 |

BDL |

1.6 |

BDL |

|

Cobalt |

1.26 to 1.4 |

0.003 |

0.29 |

0.00 |

0.51 |

0.01 |

NR |

NR |

|

Chromium |

0.032 to 0.253 |

BDL |

0.02 |

0.01 |

0.01 |

BDL |

NR |

NR |

|

Copper |

4.16 to 5.2 |

0.395 |

0.02 |

0.01 |

33 |

0.01 |

12 |

0.07 |

|

Iron |

1.6 to 1.64 |

10.9 |

9.19 |

2.72 |

1.38 |

3.29 |

27 |

0.28 |

|

Manganese |

259 to 420 |

4.5 |

135.34 |

78.14 |

88.87 |

172.6 |

100 |

139 |

|

Nickel |

0.71 to 0.76 |

0.034 |

0.20 |

0.03 |

0.31 |

0.01 |

0.31 |

BDL |

|

Lead |

0.04 to 0.05 |

0.086 |

BDL |

BDL |

0.1 |

0.01 |

BDL |

BDL |

|

Sulfur |

833 to 849 |

41 |

985 |

732 |

515.56 |

584.44 |

NR |

NR |

|

Sulfate (ICP) |

3,567 to 3,700 |

NM |

2,955 |

2,196 |

NM |

NM |

4623 |

1315 |

|

Zinc |

36.7 to 330 |

3.39 |

24.01 |

0.52 |

126.78 |

0.38 |

270 |

0.18 |

|

pH |

|

|

|

|

3.76 |

6.53 |

|

|

|

Acidity |

1.4 |

NM |

|

|

|

|

|

|

|

Total Alkalinity |

BDL |

NM |

|

|

BDL |

1170 |

|

|

B.15.6 BCR Performance

Table B.15-1 shows the examples of influent and effluent concentrations over eight years. In general, the metal removal efficiencies for arsenic, aluminum, cadmium, cobalt, chromium, copper, nickel, lead, and zinc were 98% or greater. Manganese was high for the influent and even higher for the effluent.

|

June 2005 – Sept. 2005 |

|

Influent Sulfate Range 1350-5200 mg/l Effluent Sulfate Range 130- 1950 mg/l |

For sulfate, at low influent concentrations, the effluent data show about a 75% sulfate concentration decrease. Sulfate reduction drops to about 30-33% at higher (> 4,000 mg/l) influent sulfate concentrations. Sulfate is available at this level, but it is possibly not distributed throughout the BCR well due to influent design. In addition, during the treatment season, the influent overloads the cell, which indicates that the residence time is insufficient. When the BCR is started in the spring, the BCR effluent sulfate concentrations are often below 200 mg/l after 6 months without new influent water.

|

June 2005 – Sept. 2005 |

|

Influent pH range 3.0 – 5.24 Effluent pH range 5.8 – 6.4 |

In 2005, as the influent sulfate increased, the pH decreased. This effect did not appear in the effluent. The effluent pH remained around a 6 pH range throughout the sampling season. The effluent pH was generally more than 2 units higher than the influent, which is expected with the bicarbonate alkalinity added by the microbial action and dissolution of limestone in the BCR.

Conductivity data are inconclusive. The field ORP measurements showed substantial results. The influent range was 217 – 417 mV, all positive readings as expected. The effluent ranged from -259 to -340 mV, with the negative range showing strong reduction throughout the sampling season.

B.15.7 BCR Monitoring

USEPA ORD monitored this BCR for almost 10 years, as did CDM Smith for Region 8. Complete data for both leachate (BCR influent) and BCR effluent are available for most years, and an upcoming publication will highlight the 10 years of operation. In addition, certain parameters are monitored on a daily basis with the operation of the chemical precipitation plant, especially when the BCR effluent is mixed with the leachate pond to increase the pH. A small chemistry lab exists on-site for this monitoring.

B.15.8 Regulatory Challenges

As with all CERCLAComprehensive Environmental Response, Compensation and Liability Act sites, differences have occurred among government entities working on the site. State and USEPA project managers have communicated with one another to manage these differences.

B.15.9 Stakeholder Challenges

The watershed has many stakeholders, including landowners, local communities, local and state government, special interest groups and several federal agencies, (including USEPA). Collaboration among the stakeholders is necessary to achieve a cleanup that is expedient, efficient, and long lasting. The Upper Tenmile site is being cleaned up using a collaborative, watershed approach. To date, USEPA has been unable to identify a potentially responsible party, so the cleanup on private land is paid with 90% federal funds and 10% state funds. Cooperating agencies have combined resources to expedite a watershed cleanup. The U.S. Forest Service has taken the lead role in cleaning up wastes on federal property within the Superfund site boundary (Beatrice, Justice, and Armstrong mines). Where individual mines involve both federal and private lands (Upper Valley Forge mine), cleanup expenses are shared by USEPA and the Forest Service, with the state of Montana paying 10%. The Luttrell repository was constructed as a regional repository to receive wastes from the Tenmile Creek and Basin Creek watershed sites. USEPA and the Forest Service share construction and maintenance costs of Luttrell repository.

Throughout the cleanup, USEPA has continued to work closely with the Forest Service, state, and local community. Community involvement is a priority in the Superfund process. USEPA uses a number of different tools and resources to promote effective, ongoing, meaningful community involvement. The goals of the Superfund community involvement program are as follows:

- Keep communities affected by sites informed throughout the cleanup process.

- Provide opportunities for communities to comment and offer their input about site cleanup plans.

- Facilitate the resolution of community issues tied to a site.

Throughout USEPA's Superfund response action at the Upper Tenmile Creek Mining Area site, the agency has provided information to the public through public meetings, the administrative record file for the site, fact sheets, and announcements published in local newspapers. USEPA participates in monthly meetings of the Upper Tenmile Watershed Committee and routinely discusses the cleanup plans with area residents and property owners. In addition, during the field season, USEPA distributes periodic construction updates and maintains a project office in Rimini, where residents are welcome to stop by with questions. Tours and briefings are offered to local officials. USEPA also provides funding to Rimini Community, Inc., to obtain independent technical assistance though a Technical Assistance Grant (TAG). The TAG was awarded in 2005 and renewed through 2011. USEPA's Community Involvement Plan for the site is available at the following web page: http://www.epa.gov/region8/superfund/mt/upper_ten/CIP_0708.pdf.

B.15.10 References

Butler, B.A., M.E. Smith, D.J. Reisman, and J.M. Lazorchak. “Metal Removal Efficiency and Ecotoxicological Assessment of Field-Scale Passive Treatment Biochemical Reactors.” Environmental Toxicology and Chemistry 30:1-8. 2010.

Publication Date: November 2013